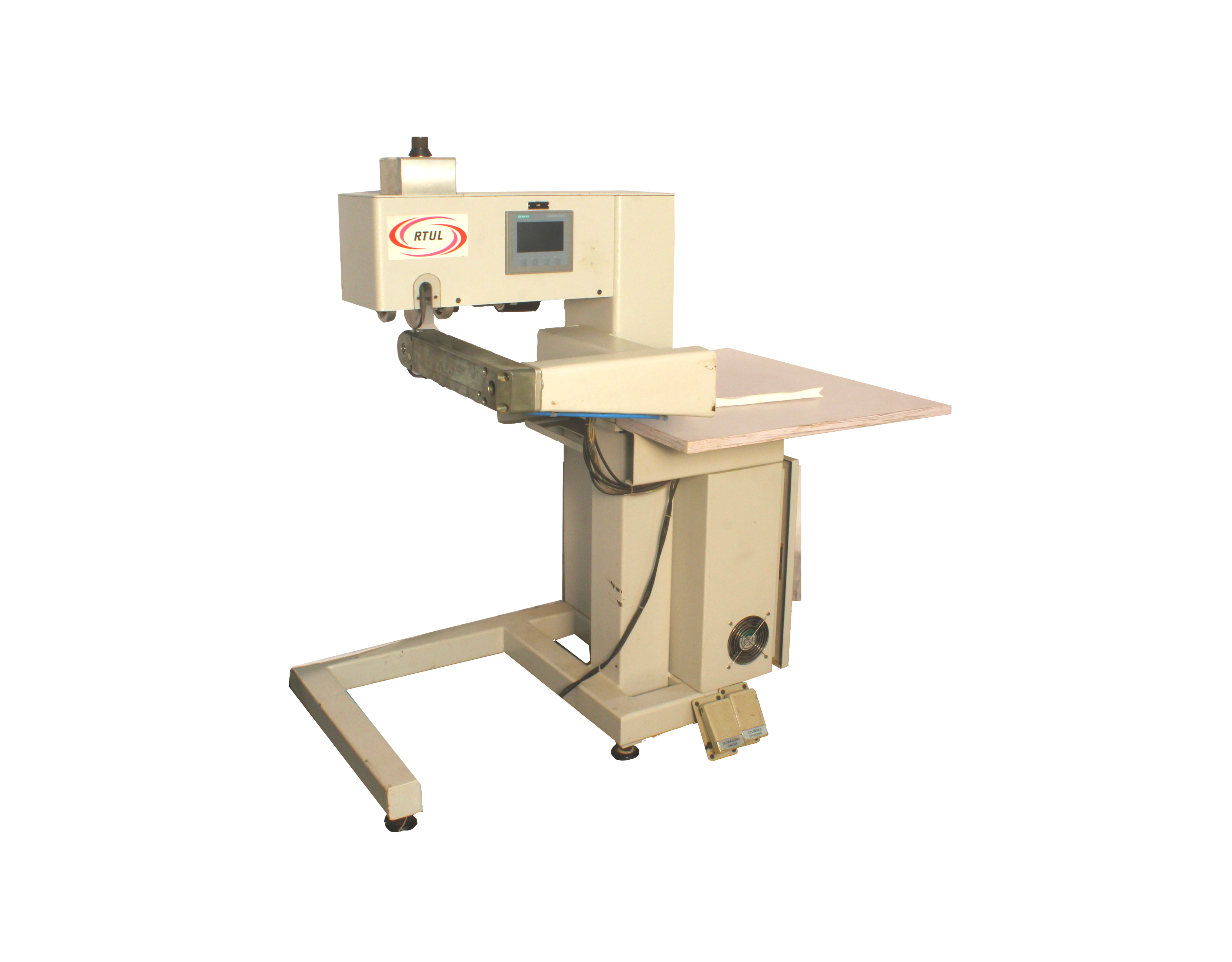

Ultrasonic Cutting Machine (Textile Slitters)

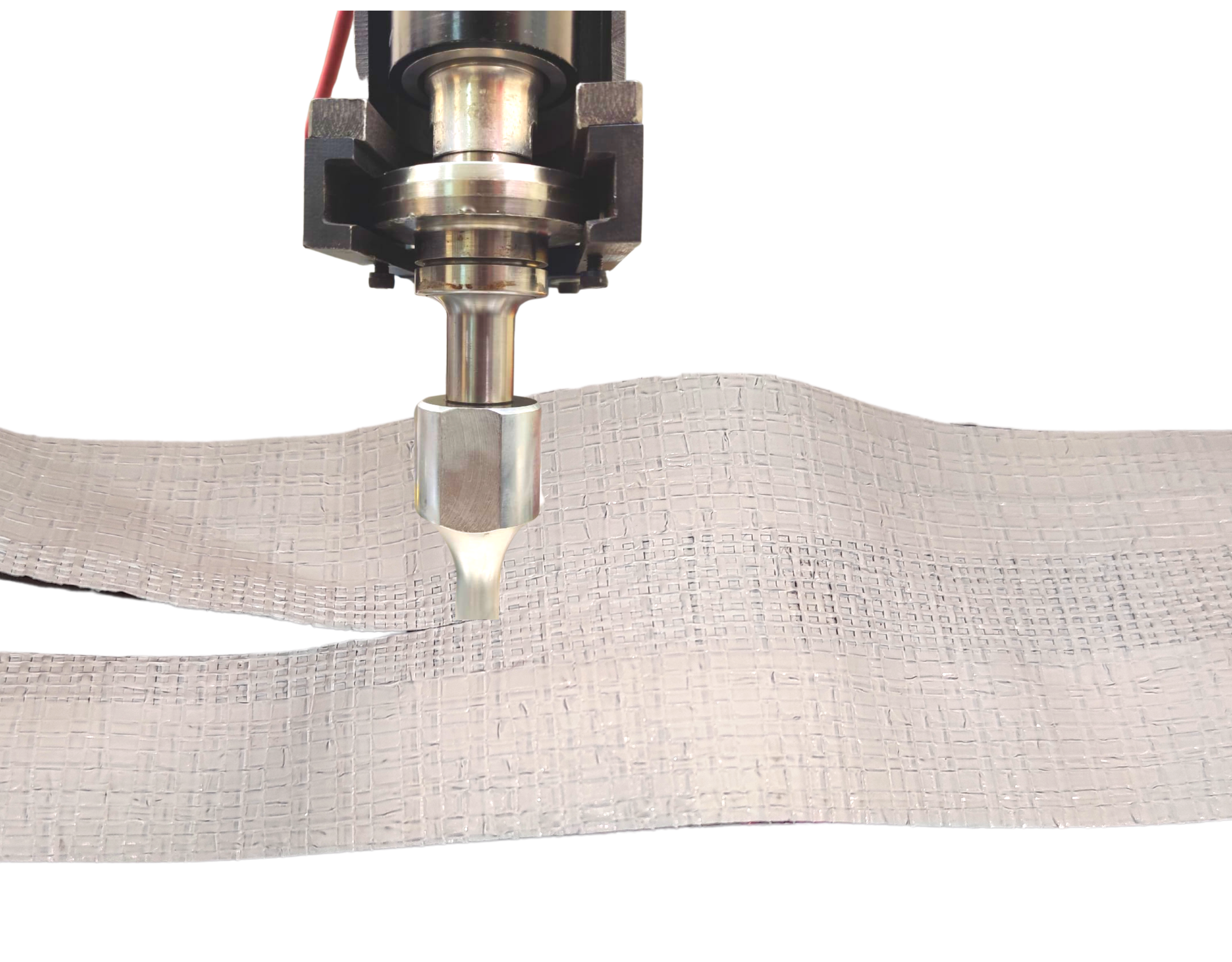

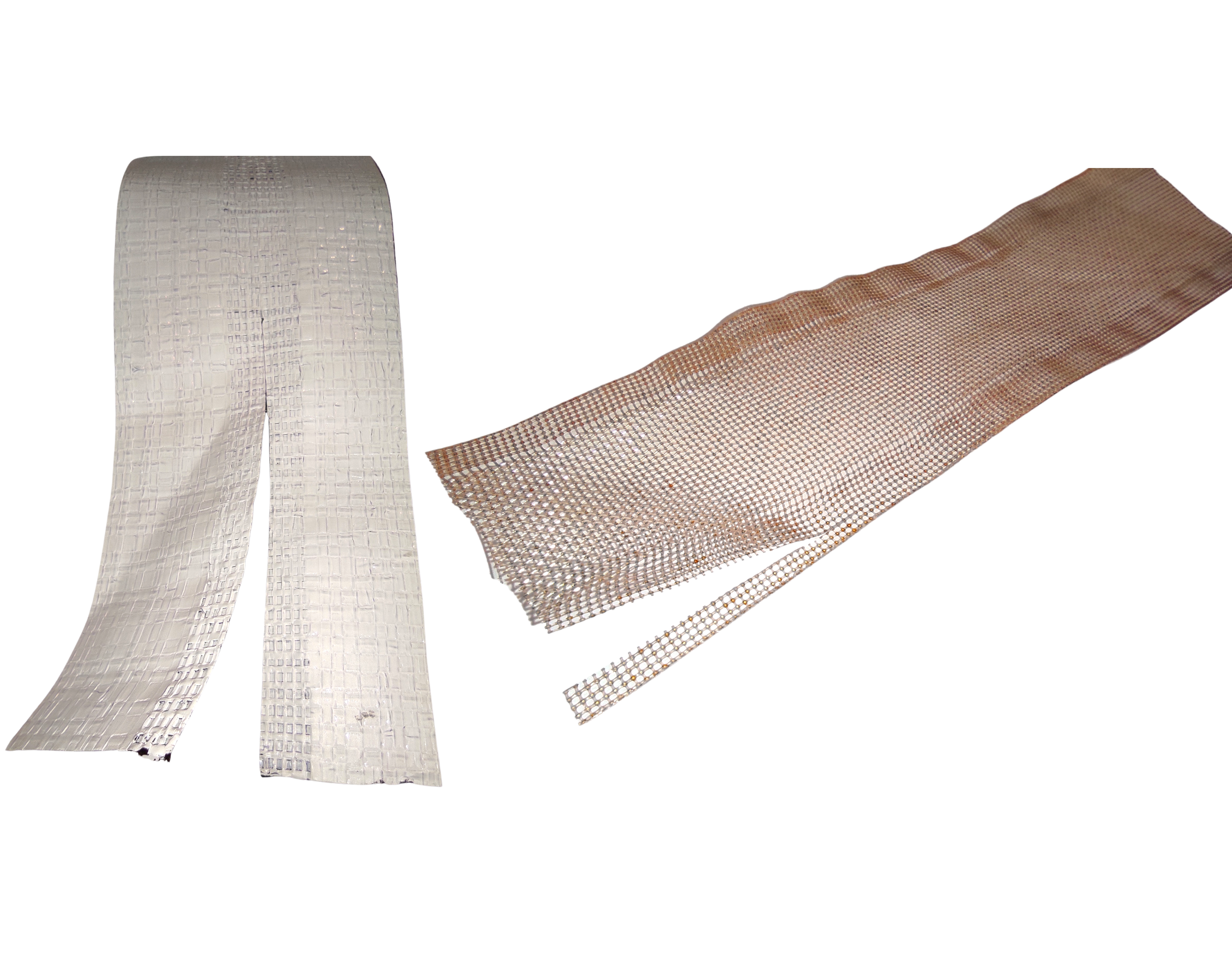

Ultrasonic cutting and sealing process is mostly used in the field of textiles on circular loom. The principal advantage of the ultrasonic seal and cut method is that the edge of the textile material, while being cut simultaneously, is sealed by the dissipation of ultrasonic energy , thereby preventing the presence of a frayed edge or the unraveling of threads, no discoloration of fabric and very strong, smooth, clean and long lasting edges without over thickness with low energy consumption. The model is mainly used for cutting of woven sacks, HDPE or PP circular woven fabric, etc.

Ultrasonic cutting is mostly used in cutting of Synthetic (Polyester, Nylon) fabric cutting, saree cutting, BOPP film sealing. The technology has tremendous advantages over other cutting methods such as cutting without pressure prevents any deformation of the material, high quality of the cut is achieved, no smudging or breaking of individual layers, reduced processing time and no heat input into the product i.e the tool remains cold.

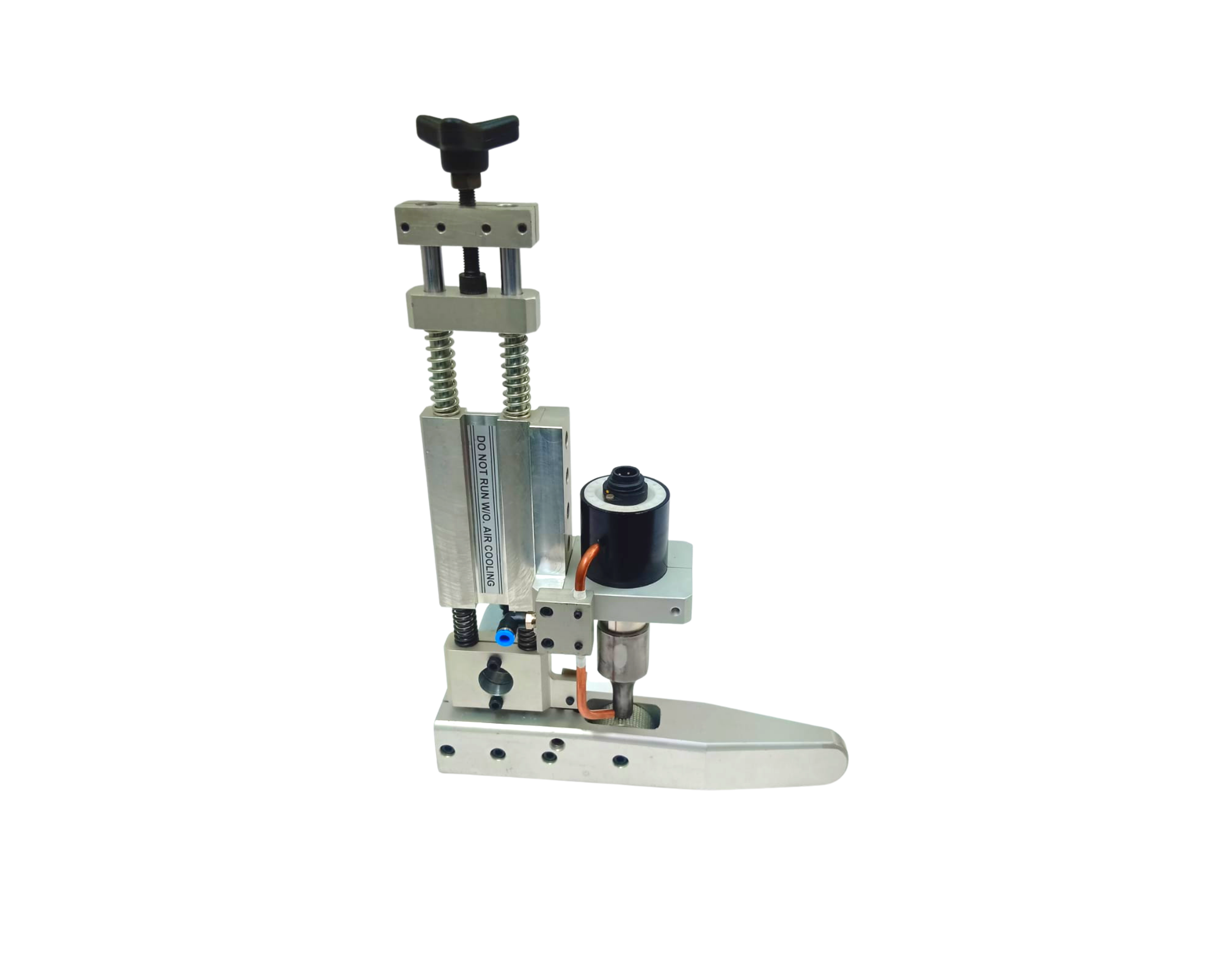

| Ultrasonic Generator | SG-40-36-500W/ SG-40-36-1000W/ SG -22-1500W |

| Ultrasonic Converter | 36 KHz/ SE 40/33 |

| Horn | Titanium |

| Working GSM | 20-140/150-240/240-300 |

| Surgical Blade | No. 23 |

| Booster with ring | Yes (Titanium) |

| Dealing & Welding area | 25 mm x 5 mm (max) |

| Ultrasonic Generator | SG-40-36-500d / SG-40-36-1000d / SG -22-1000d |

| Ultrasonic Converter | 36IW /SE 40/33, 36IWz/SE 40/33, 20KHz/SE-50/50-4 |

| Horn | Steel or Titanium |

| Working GSM | 50 / 50-80 / 80-140 |

| MS/ Steel Roller | Yes |

| Booster with ring | Yes (Titanium) |

| Spring loaded attachment | Yes |

| Held area (Dia. in mm) | 5 mm/ 5 mm/ 5 to 10 mm (max) |

.png)

.png)

.png)