Creating Strong Bonds with Thermoplastics: Material Compatibility Matters

When it comes to joining thermoplastic parts, achieving a strong and lasting bond is one of the crucial factors: chemical compatibility.

The materials need to be fundamentally compatible to form a secure connection. Merely melting them at the same temperature isn’t enough.

Even if two materials melt at the same temperature, they may not form a molecular bond if they’re not chemically compatible.

For instance, polypropylene and polyethylene share similar appearances and many physical properties as semi-crystalline materials. However, they lack chemical compatibility, preventing them from bonding to each other through welding.

In many cases, it’s essential to weld similar materials together, like joining ABS to ABS.

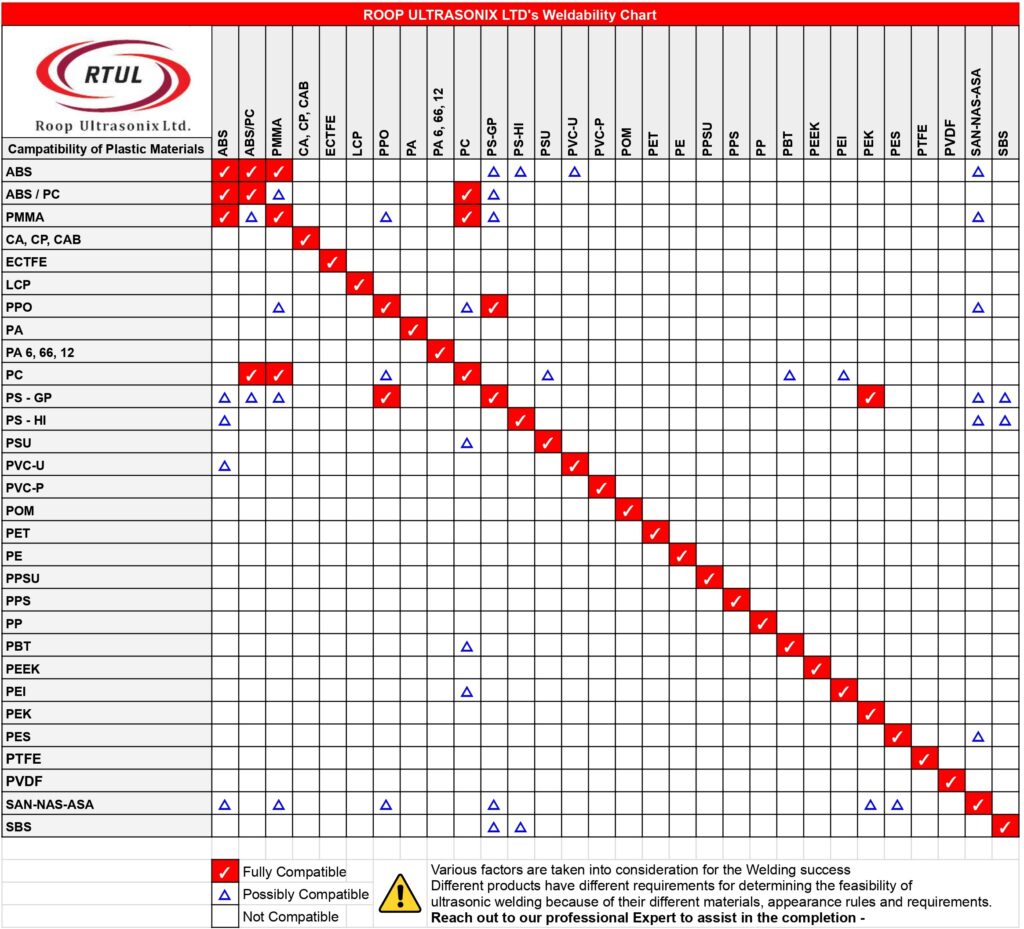

Referring to the above chart we can see that

ABS is Fully Compatible with materials like ABS, ABS/PC, and PMMA. Whereas ABS may or may not be compatible with PS-GP, PS-HI, PVC-U, and SAN-NAS-ASA. There may be a possibility of Compatibility in such cases.

And ABS is not compatible with materials like CA, CP, CAB, ECTFE, LCP, PPO, etc.

Not all plastics weld the same!

While many factors affect welding success, different materials have unique needs. To ensure successful welding, factors such as materials, appearance, and specific requirements are taken into consideration.

Contact our expert for personalized assistance and any sort of query.

.png)

.png)

.png)