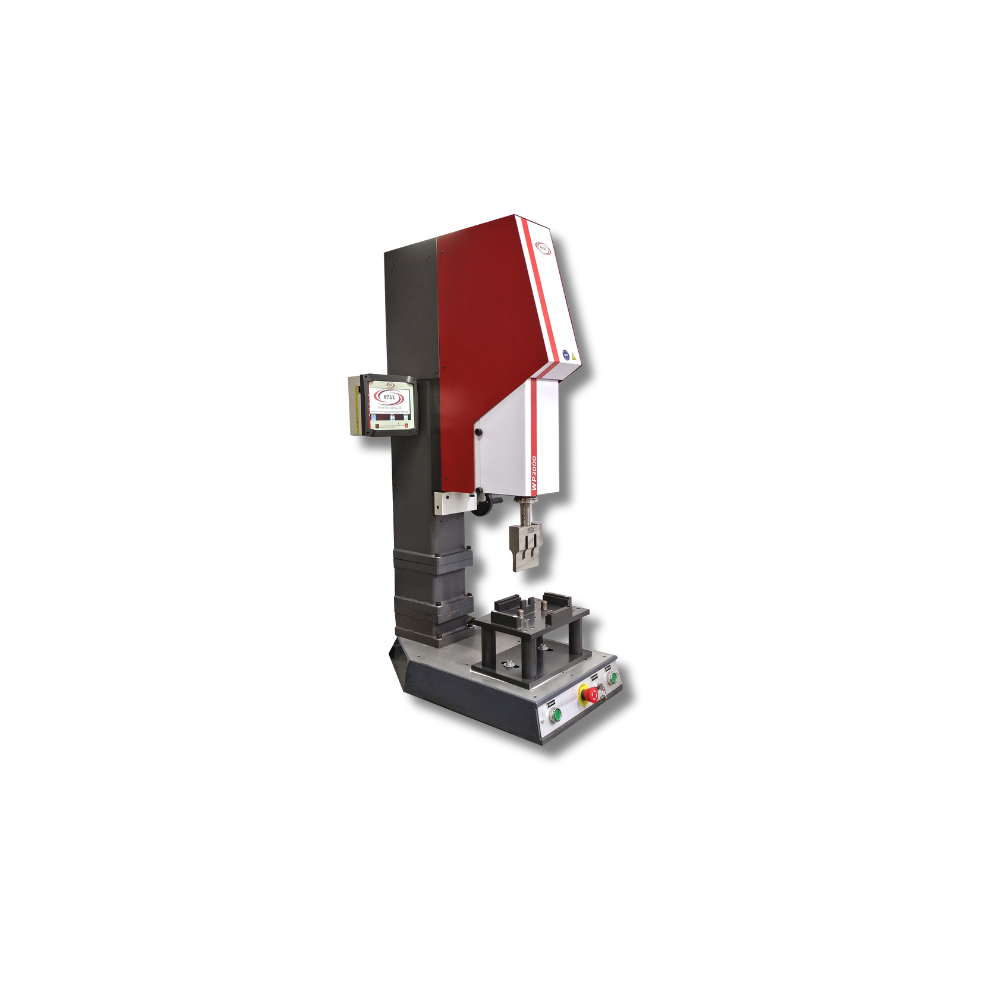

Ultrasonic welding: Advanced technique for metal and plastics joinery

Today’s industrial production and operations require agile processes to save time and money. Ultrasonic welding (USW) is a crucial process used for joining materials like metal and plastics components. With advanced technology and solid mechanical vibrations, it is the fastest method by which results are achieved. RTUL is a market leader which deals in making components for industries like automotive, aerospace, appliances, electronics and medical devices. As a reliable ultra...

- Read More.png)

.png)

.png)