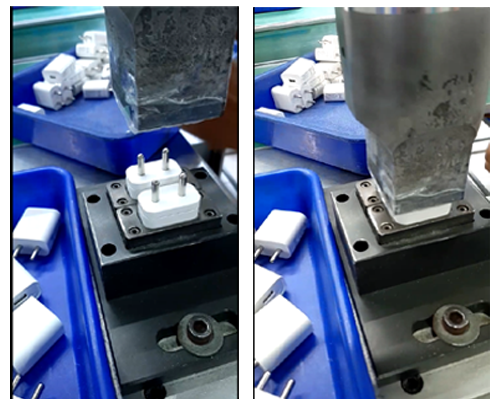

The Task

The task was to perform ultrasonic welding of the adapter by joining the upper and lower parts of the adaptor with plugs facing upward. The challenge was to weld two numbers of adaptors in a single stroke with plugs.

The Solution

To meet the current requirement of welding two adaptors together in a single stroke, we have designed an appropriate sonotrode with a cavity that ensures adequate transmission of ultrasonic vibrational energy along the joint perimeter.

By utilizing a digital ultrasonic welding setup and this specialized horn, we have successfully achieved a solution for welding the current part profile in a single stroke. Our machines are designed with a modular structure, making them easy to integrate into automated manufacturing systems. The microprocessor controller unit is already equipped with all the necessary hardware and software elements to control conveyors, linear, and rotary table units.

The Advantages

1. The cost of production is very low.

2. The welding process creates a strong bond and a secure, neat seal.

3. The welding system offers high precision with single-stroke welding.

4. The equipment used for ultrasonic welding is very compact.

5. The resulting welding joints are visually appealing.

6. Ultrasonic welding produces high-quality results.

7. The welding joints are free from any gaps or empty spaces

.png)

.png)

.png)