The Task

To design an ultrasonic metal welding machine to weld brass terminals. An electronics company will use brass terminals in switches, sockets, etc to achieve more strength and highly conductive welds.

The Solution

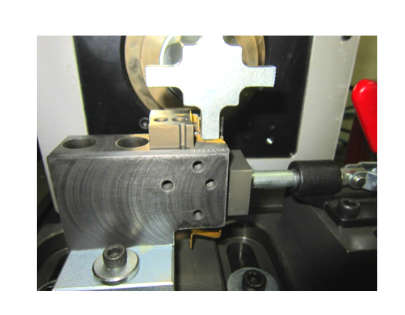

In this case, the challenge was processed by designing an ultrasonic metal welding machine consisting of 4000N press, SG-22 3000 W, 20kHz generator, half wavelength special steel alloy sonotrode, special fixture and micro-processor controller 4 to achieve strong welds. The machine located the terminals precisely and guarantees that welding occurs at exact location.

The Advantages

- High production rates

- Less processing time

- Higher strength, reliability and quality

- Uniform weld pattern

- Low heat generation

- No additional joining material

- Can easily be integrated into automatic production lines

- Highly conductive welds achieved

.png)

.png)

.png)