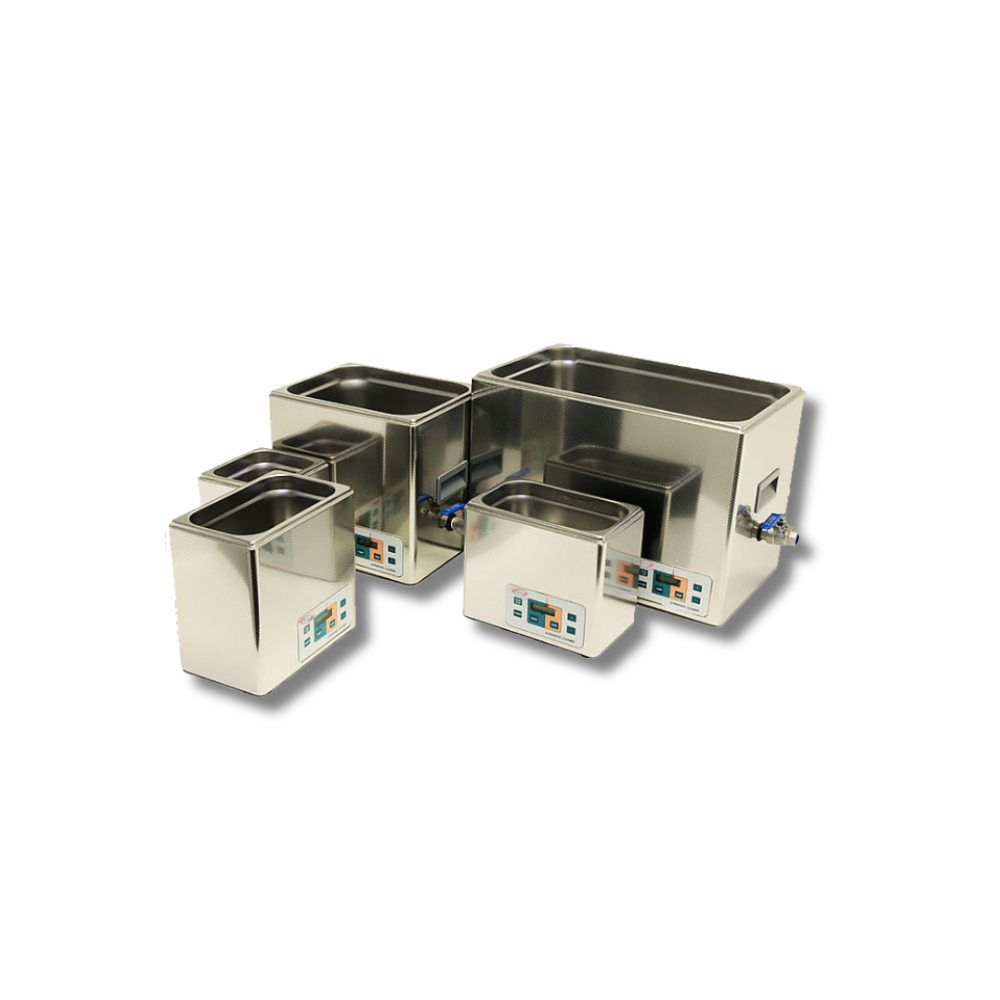

INDUSTRIAL TANKS

It consists of process tank with ultrasonic tube resonator & ECO generator. Tube resonator is provided at the tank bottom to provide ultrasonic vibrations in the liquid, which uniformly cleans the component. SS heater is provided at the bottom for heating the solution. A level switch is provided to switch off ultrasonic parts and heater to avoid damage due to dry running. A drain valve is also provided for periodical drain of complete solution manually. The inner tank is provided with insulation.

The Online Filtration helps in removal of the contamination out of the system and ensures a clean bath. The clean bath helps in sustaining the cleaning level for a longer duration of time / period.

| Details | Model IT 120 | Model IT 280 | Model IT 360 | Model IT 500 |

| Tank Capacity | 12 Liters | 28 Liters | 36 Liters | 50 Liters |

| Tank Size | 280*220*200 mm | 485*275*200 mm | 500*360*250 mm | 550*475*275 mm |

| Tank Material & Thickness | SS 316 – 2 mm | SS 316 – 2 mm | SS 316 – 2 mm | SS 316 – 2 mm |

| Ultrasonic Power (Avg/PP) | 300 W | 600 W | 750 W | 1500 W |

| Bonded Transducers | 4 Nos. | 8 Nos. | 15 Nos. | 20 Nos. |

| Frequency (kHz) | 20/30/40 | 20/30/40 | 20/30/40 | 20/30/40 |

| Heater | 2 kW | 3 kW | 4 kW | 5 kW |

| Temperature Control Variable | Provided | Provided | Provided | Provided |

| Timer Variable | Provided | Provided | Provided | Provided |

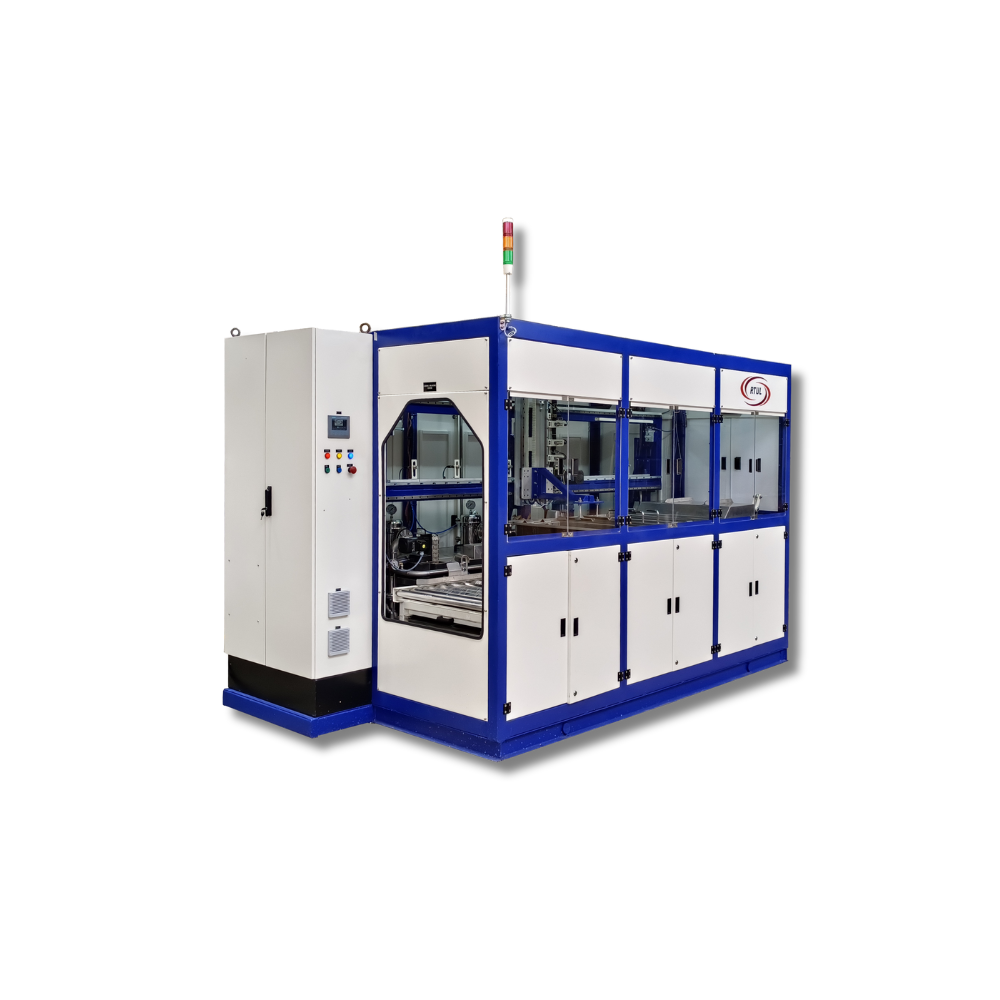

| TYPE | IT- 50 | IT- 70 | IT- 100 | IT- 115 | |

| Tank Size ( L x W x D ) | mm | 550 X 350 X 300 | 600 X 400 X 350 | 615 X 410 X 500 | 615 X 410 X 550 |

| Overflow | mm | 250 | 300 | 410 | 460 |

| Tank Body | SS | 304 | 304 | 304 | 304 |

| Tank Material | SS | SS 304/ 2mm | SS 304/ 2mm | SS 304/ 2mm | SS 304/ 2mm |

| Tank Capacity | Litres | 50 | 70 | 100 | 115 |

| Ultrasonic transducer | Nos | 15 | 20 | 20 | 24 |

| Ultrasonic Eco generator | Nos | 1 | 1 | 1 | 1 |

| Ultrasonic Frequency | Khz | 30 | 30 | 30 | 30 |

| Ultrasonic power (Average/ Peak) | Watts | 750/ 1500 | 1000/ 2000 | 1000/ 2000 | 1200/ 2400 |

| Operator Panel | Provided | Yes | Yes | Yes | Yes |

| Time control | Provided | Yes | Yes | Yes | Yes |

| Temperature control | Provided | Yes | Yes | Yes | Yes |

| Heater | KW | 4 | 4 | 4 | 4 |

| Drain valve | 1″ Manual | Yes | Yes | Yes | Yes |

| Overflow valve | 1″ Manual | Yes | Yes | Yes | Yes |

| Basket SS ( Lx W x D ) | mm | 510x315x275 | 560x365x325 | 575x375x375 | 575x375x425 |

| SS Lid | Provided | Yes | Yes | Yes | Yes |

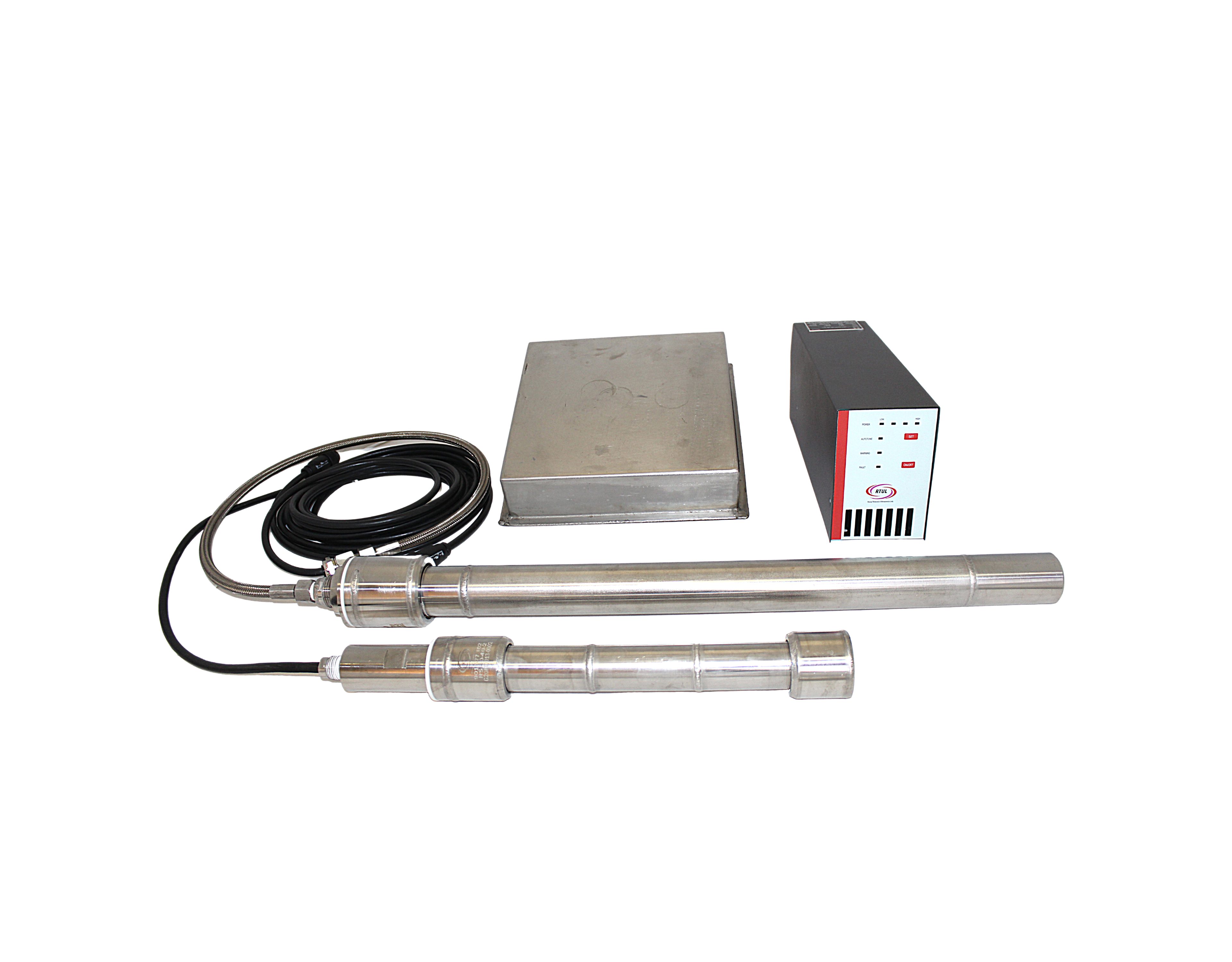

- Efficiency more than 95%

- Absolute & fully automatic monitoring, independent of voltage fluctuations

- Optimum operating frequency under all operating conditions

- Optimum output power with all variations of temperature, solution level and workload

- Wave pulse modulation ensures high cavitation, therefore resulting in High cleaning action

- Protection against short circuit and idling conditions

- Power variation from 50 - 100% with potentiometer integrated in the Front Panel

- Latest electronic component (IGBT) technology

- Each generator module is an independent generator

- Versatile provision for mounting

- Practically maintenance-free

.png)

.png)

.png)