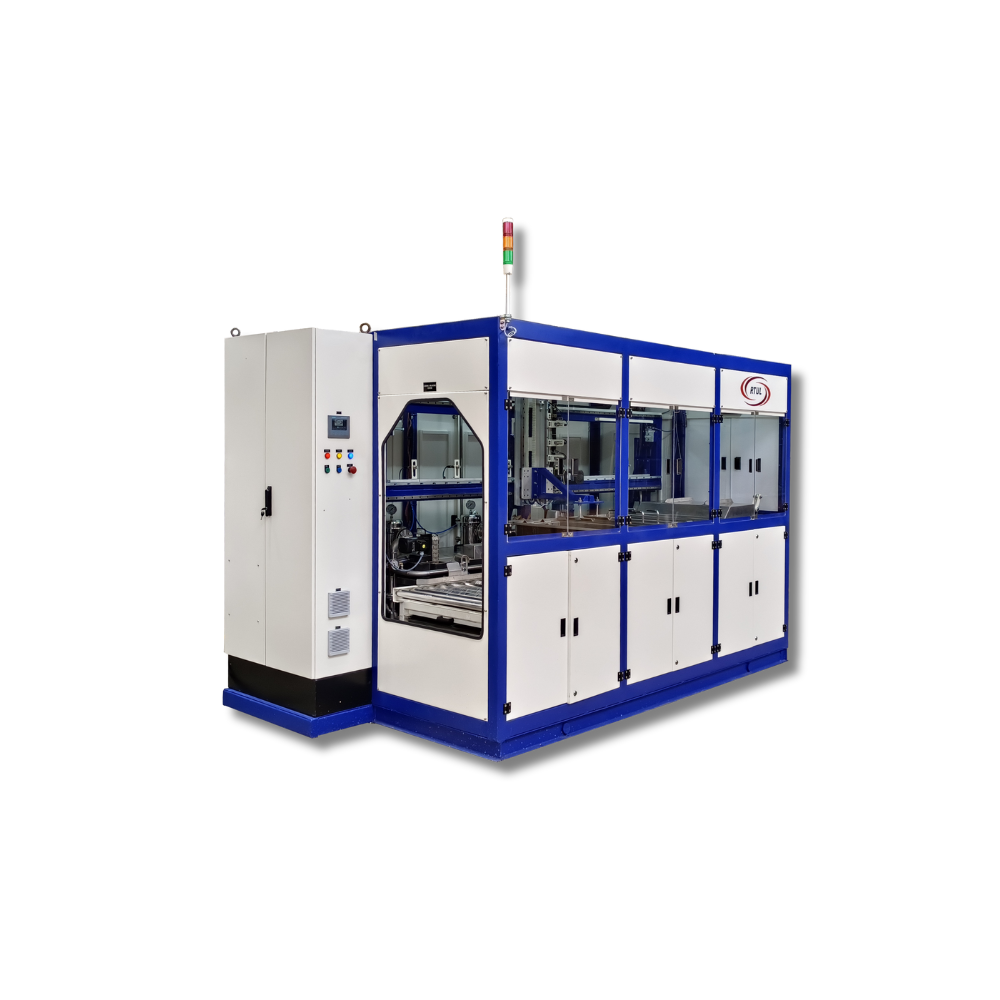

Mouldeto

Mouldeto is designed to do maintenance cleaning of complicated parts. It is ideal for cleaning equipment that could get marks or cuts through cleaning.

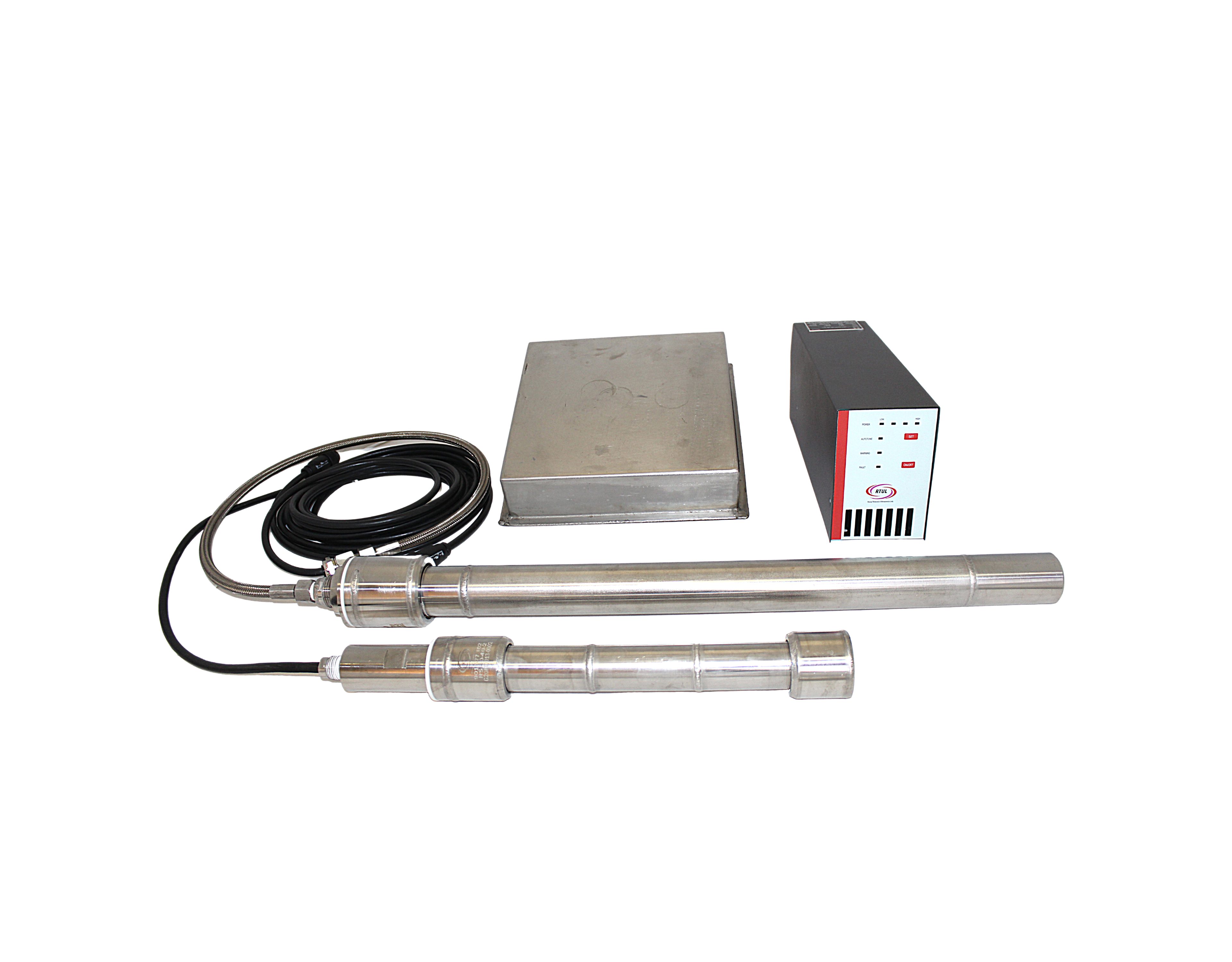

Ultrasonic cleaning is gentle yet precise. It leverages the property of water to cavitate when ultrasonic waves are passed through it. The bubbles formed from cavitation reach the most inaccessible holes and crevices.

Mould Cleaning Process

1. Ultrasonic wash at 80°C for about 5-15 minutes

2. Rinsing with air bubble agitation for about 1 minute

Optional

3. Preservation with dewatering or hot passivation for about 1 minute

4. Inspection / manual intervention

| Sr. No. |

Tank Capacity |

Tank (mm) | O/F @ | Effective Basket | Max. Mould Size | Max. Weight |

Ux Effect | Heating Effect |

| 1 | 70 | 600*400*400 | 300 | 450*300*150 | 400*250*125 | 50 | 1.5 KW | 4 KW |

| 2 | 115 | 615*410*650 | 550 | 465*310*400 | 415*260*350 | 50 | 3.0 KW | 4 KW |

| 3 | 180 | 750*500*610 | 400 | 600*350*160 | 550*300*110 | 100 | 3.0 KW | 8 KW |

| 4 | 300 | 900*700*780 | 550 | 700*450*580 | 720*380*530 | 200 | 4.5 KW | 12 KW |

| 5 | 400 | 1100*700*780 | 550 | 900*450*580 | 800*380*530 | 300 | 5.0 KW | 12 KW |

| 6 | 500 | 850*850*900 | 700 | 650*750*650 | 560*680*580 | 400 | 6.0 KW | 14 KW |

| 7 | 700 | 1050*950*940 | 700 | 850*750*600 | 750*680*500 | 700 | 9.0 KW | 20 KW |

- Die casting moulds

- Extrusion tools

- Glass moulds

- Plastic injection moulds

- Press tools

- Punch tools

- Saw blades

- Wood cutters

- Remarkable cleaning outcome

- Fast cleaning process

- Simple handling

- Safe equipment

- Reduced manual work

.png)

.png)

.png)