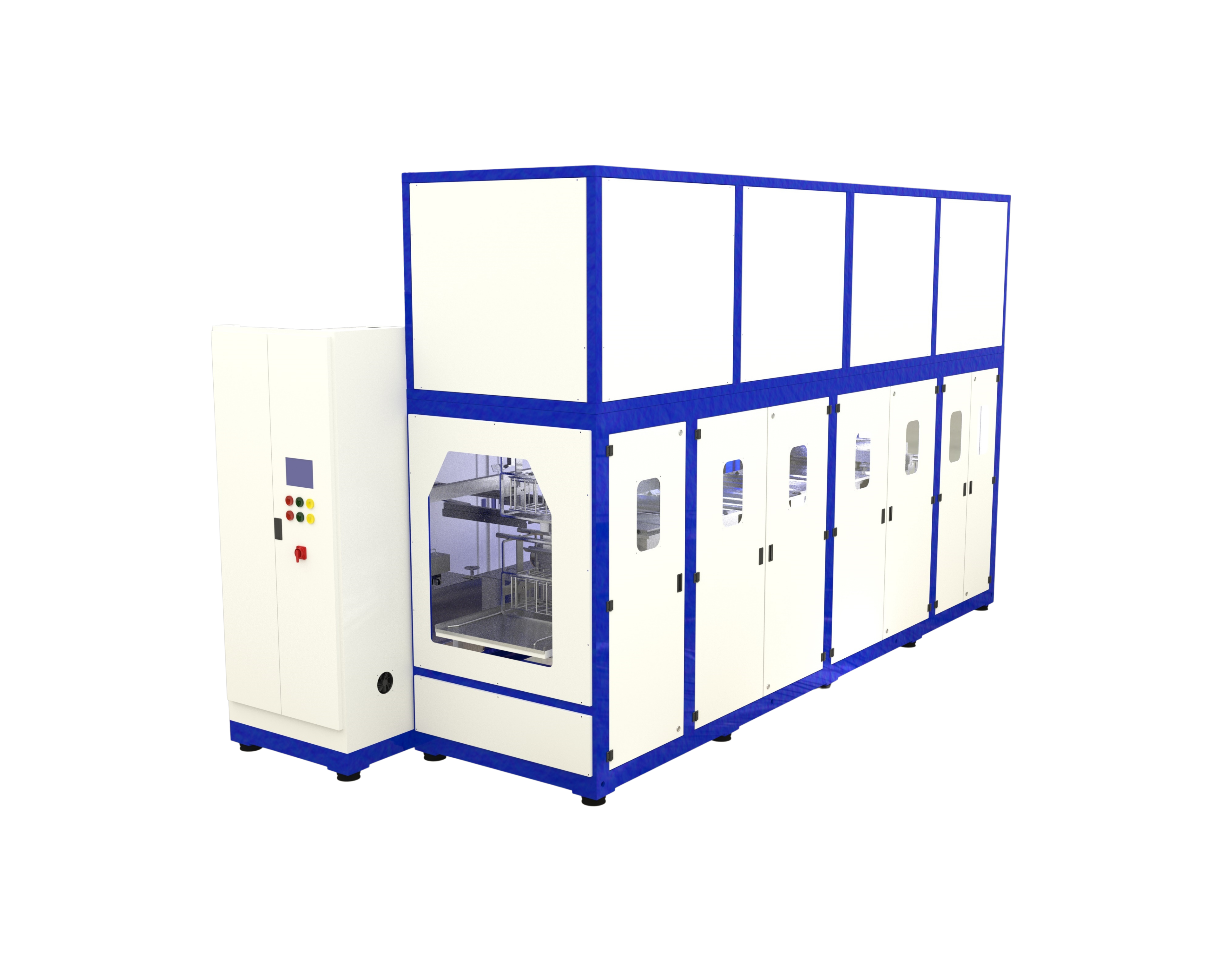

Solvent based Cleaning Systems

Ultimate Combination of Flexibility and Efficiency:

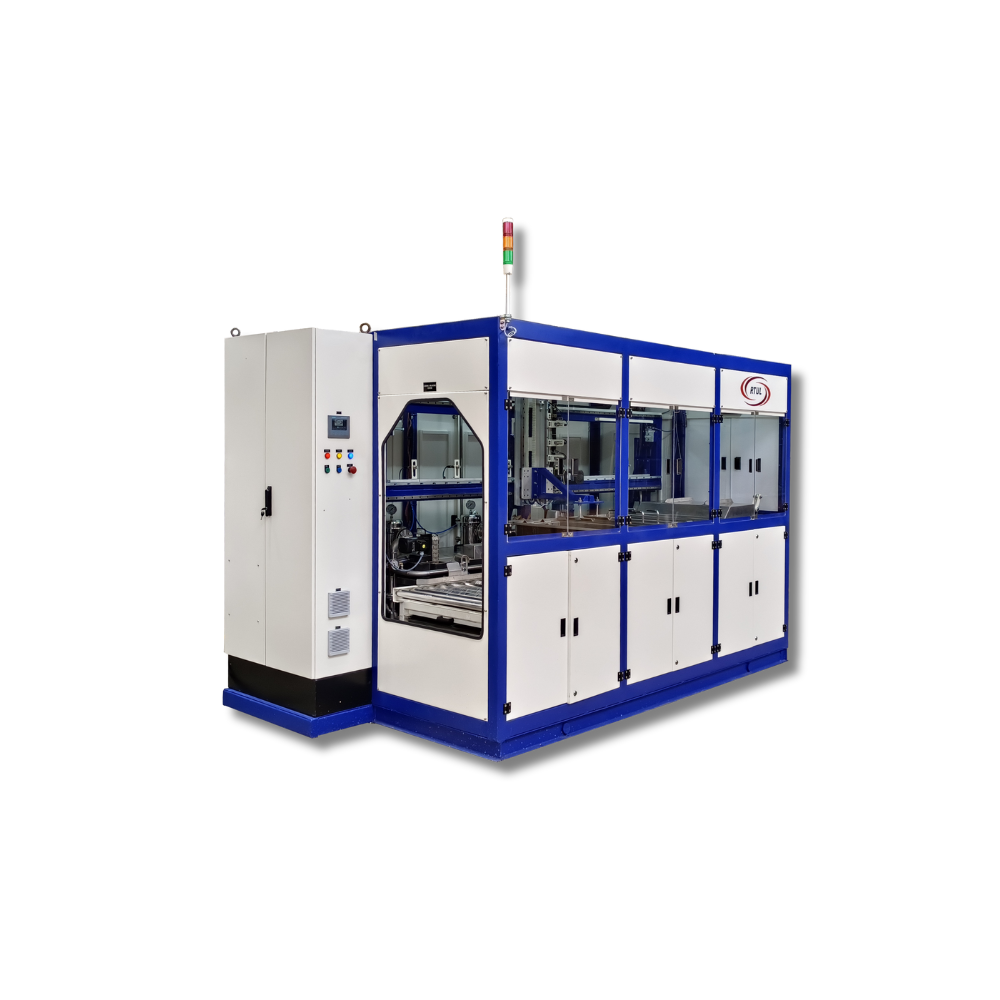

The RT-UCL-EVD solvent based ultrasonic cleaning machine from RTUL are well known for their high level of cleanliness and cleaning the parts a form any solid or liquid contamination. Especially designed for use with the Eco-friendly 3M Novec Solvents, The EVD 1 is the ideal combination of affordable cleaning and safe work environment.

Cleaning Chemical

Detergent/cleaning solvent is essential for achieving high cleanliness level. During ultrasonic washing we require a high pH level cleaner. RTUL’s cleaning solvent is a strong cleaning solution which can work effectively on the most difficult contaminations without eroding surface layer of the component to be cleaned.

| MODEL NO. | EVD 25 | EVD 50 | EVD 100 |

| Dimension: | |||

| Process Tank | 25 Litres | 50 Litres | 100 Litres |

| Tank Size | 494 x 227 x 277 mm | 545 x 300x 410 mm | 715 x 370 x 475 mm |

| Tank Material | S.S. – 304 | S.S. – 304 | S.S. – 304 |

| Basket Size | 350 x 112 x 90 mm | 415 x 225 x 150 mm | 600 x 300 x 150 mm |

| Tank Details: | |||

| Collection Tank | 44 Litres | 73 Litres | 140 Litres |

| Distillation Tank | 53 Litres | 93 Litres | 170 Litres |

| Clean Tank | 65 Litres | 150 Liters | 265 Litres |

| Electrical Power: | |||

| Heat in Collection Tank | 2 Kw | 2 Kw | 4 Kw |

| Heat In Distillation tank | 4 Kw | 4 Kw | 8 Kw |

| Bag Filter | Single Line, Bag Type | Single Line, Bag Type | Single Line, Bag Type |

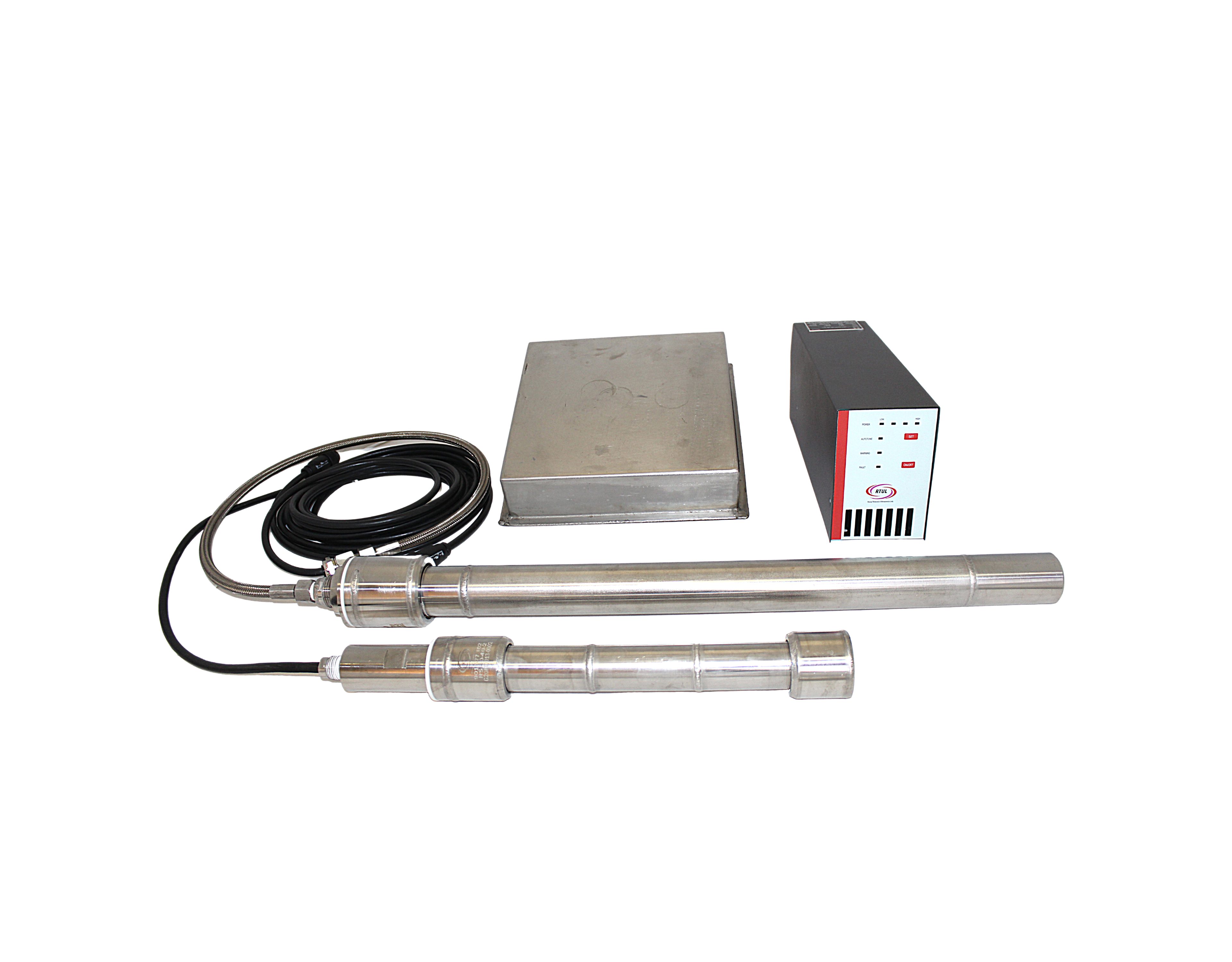

| Ultrasonic | 40 Khz+80 Khz (600W) | 40 Khz+80 Khz (1000W) | 40 Khz+80 Khz (1500W) |

- High Level of Cleanliness and process efficiency.

- Completely operated in Vacuum - ensuring ultra - low solvent consumption and thus reduction of solvent purchases.

- Complete Closed Loop Operations - Ensuring near zero emissions maintaining a healthy and pollution free environment.

- Revolutionary Dual frequency technology (40 Khz and 80 Khz) ensuring highest level of precision in cleaning process.

- Minimized floor space with user friendly access for maintenance.

- Efficient energy management and Heat Recovery.

- Lower Electric Consumption.

- Reduction in regulatory requirements - No hazardous material handling and hazardous waste generation.

- Single tank, Operated under complete vacuumed conditions.

- Process steps includes Rotation, Solvent Immersion, Vapour Degreasing and Vacuum drying.

- SS (stainless steel) process tank with bright anneal finish.

- Dual Frequency of 40kHz and 80kHz.

- Continuous distillation for recycling for recycling of solvent to guarantee cleanliness standards.

- Parts movement programmable according to the costumer’s needs i.e rotation, angular movement , no movement.

- Dual bag filters for filtration. Filter for emission free change of bag filters.

- Colourful touch screen HMI for clear process visualization with preset service programs.

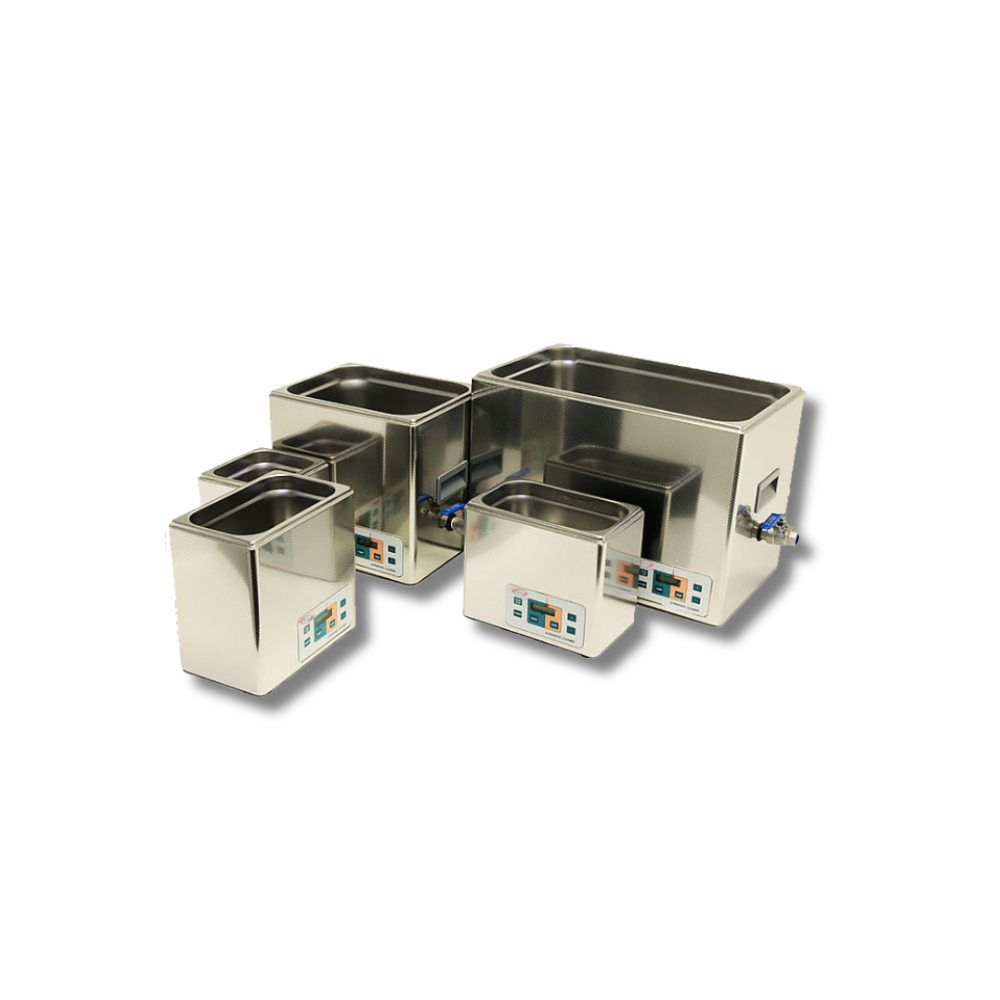

- Standard 25 Litres, 50 Litres and 100 Litres configuration for configurations available with customization possible upon request.

.png)

.png)

.png)