WP Series Metal Welding

Ultrasonic metal welding is described as a friction welding process, where oxides and other contaminations present on the material surfaces are broken up, and the parts to be welded are brought together under simultaneous pressure. Molecular bonding, similar to the conventional cold-press welding, then takes place.

The greater the challenge, the stronger our commitment:

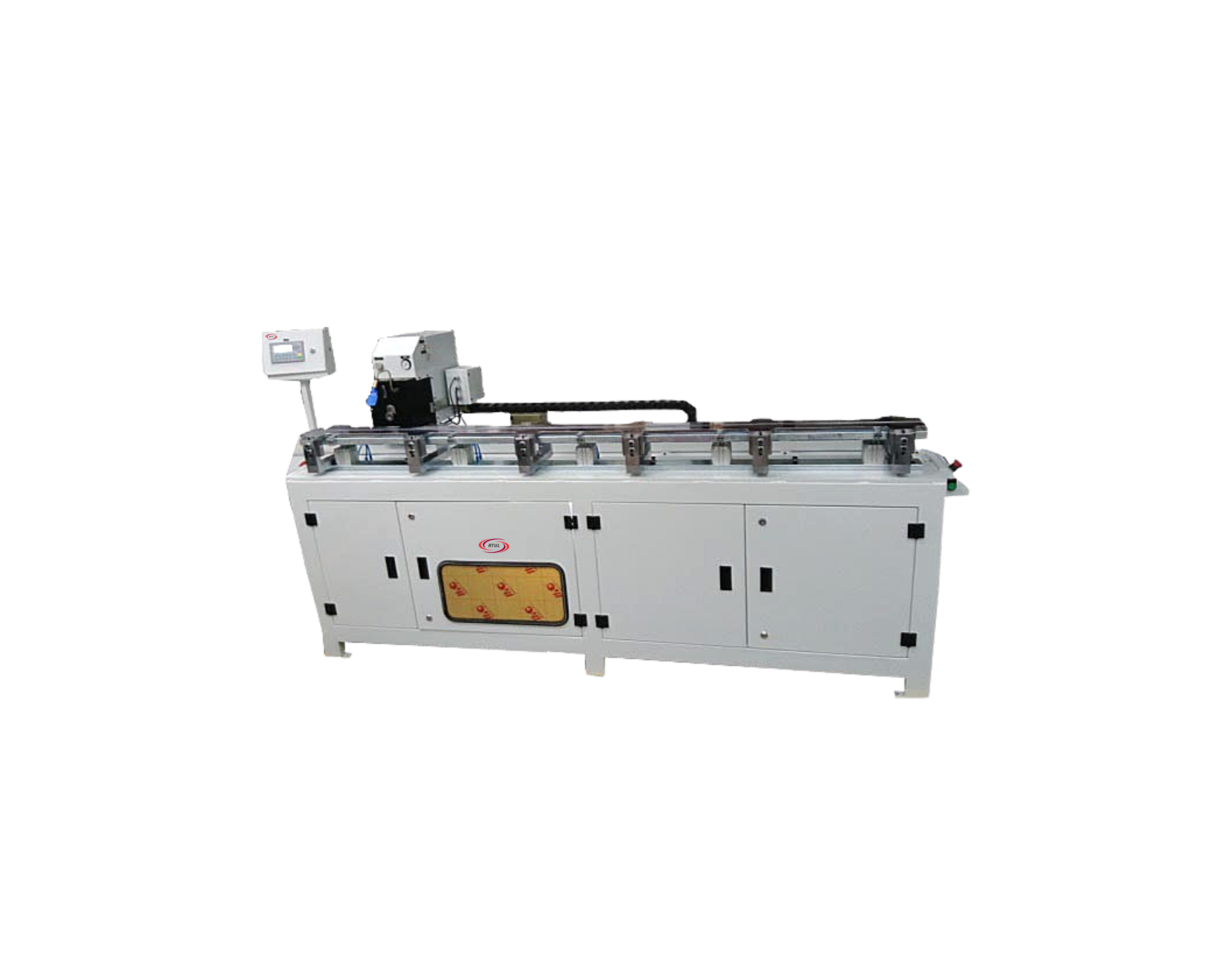

Ease of automation, weld parameter monitoring and statistical process control are demanded by the market, as they are prerequisites for the use of ultrasonic metal welding in industrial production Environments. On the basis of solid engineering know-how and precision machine building, we offer application specific welding systems for semi- and fully automated production processes.

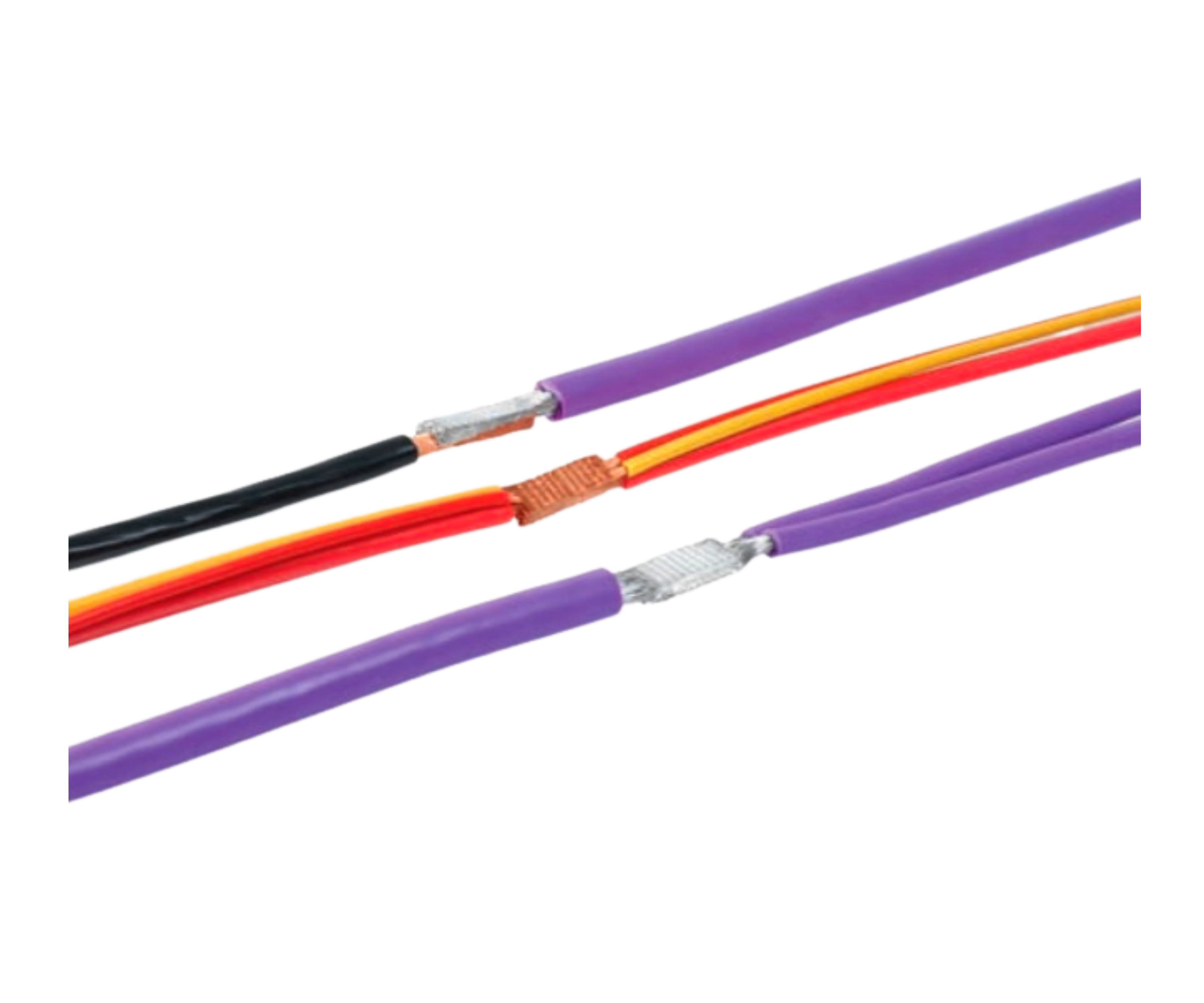

- Welds similar and dissimilar non-ferrous material.

- Excellent weld quality and helium tight welding.

- Fast, reliable, consistent welding quality with microprocessor controller.

- No need of any filler materials.

- Low power consumption.

- Clean and safe process (no sparks, flames and smoke formation) and hence, environmental friendly.

- 100% bond conductance.

- Can be easily automated.

- Continuous welding operation possible.

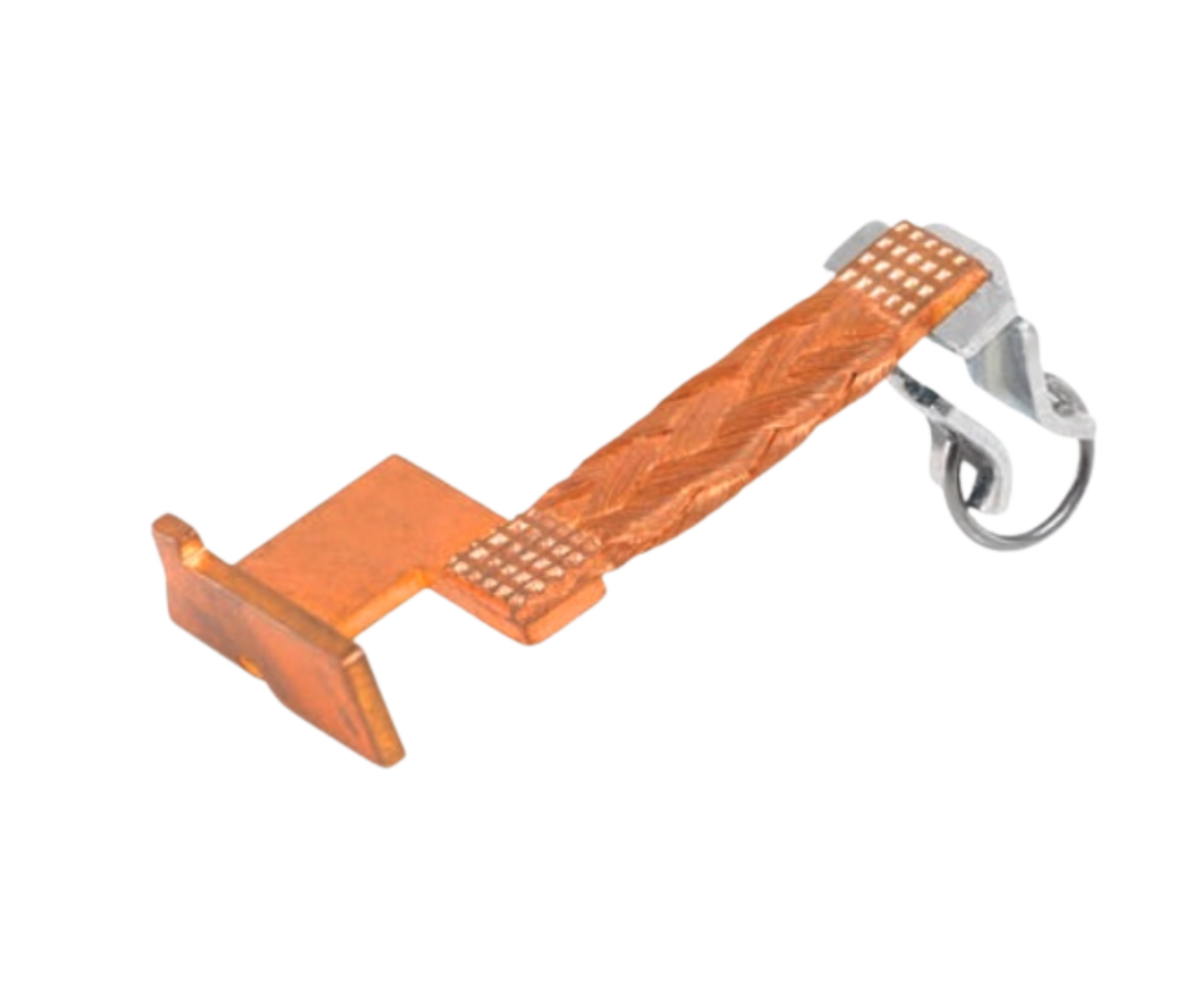

- Switchgears

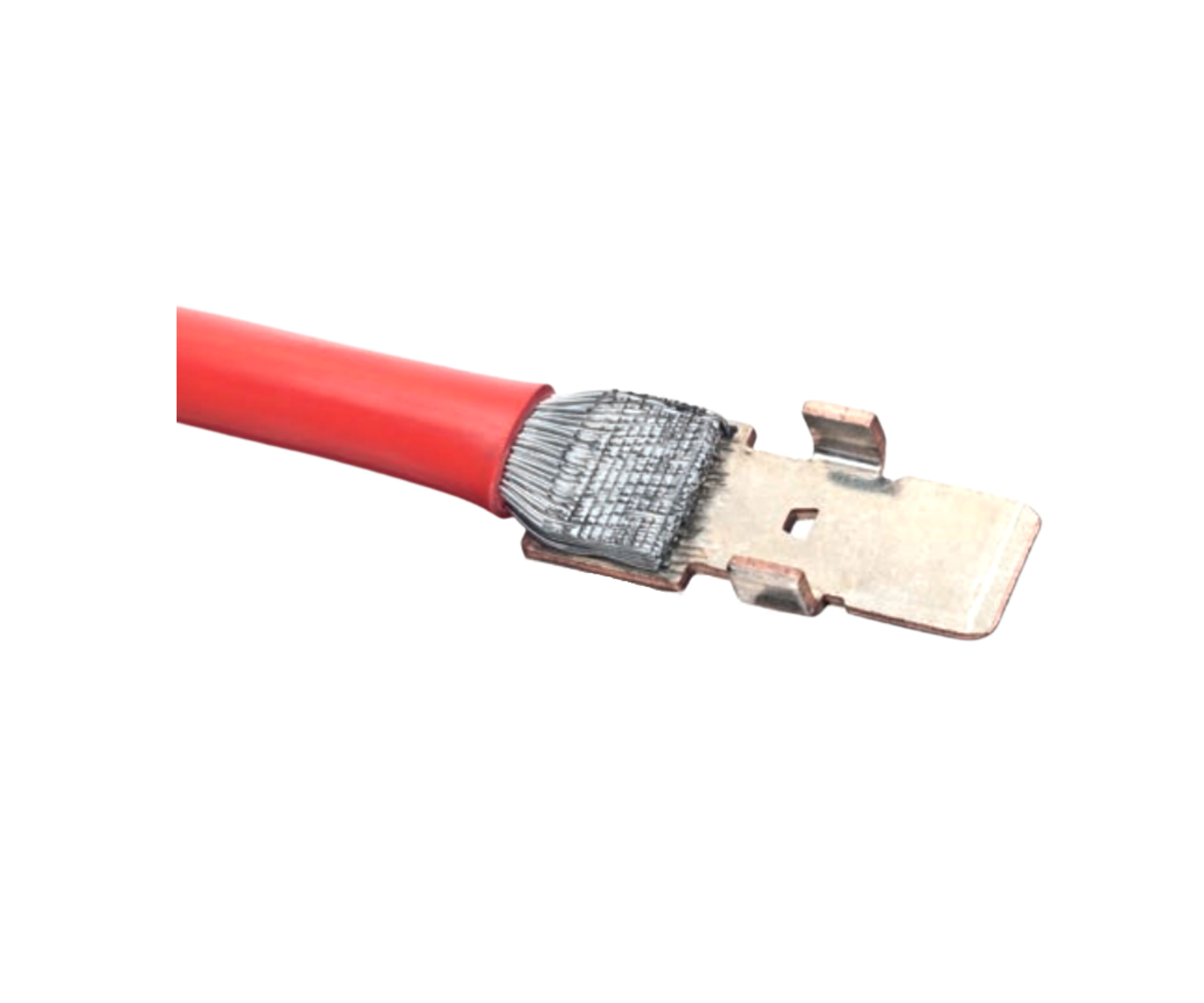

- Electrical Connectors

- Coils

- Solar Panels

- Collectors For Solar Heating Systems

- Telecommunication Equipments

.png)

.png)

.png)