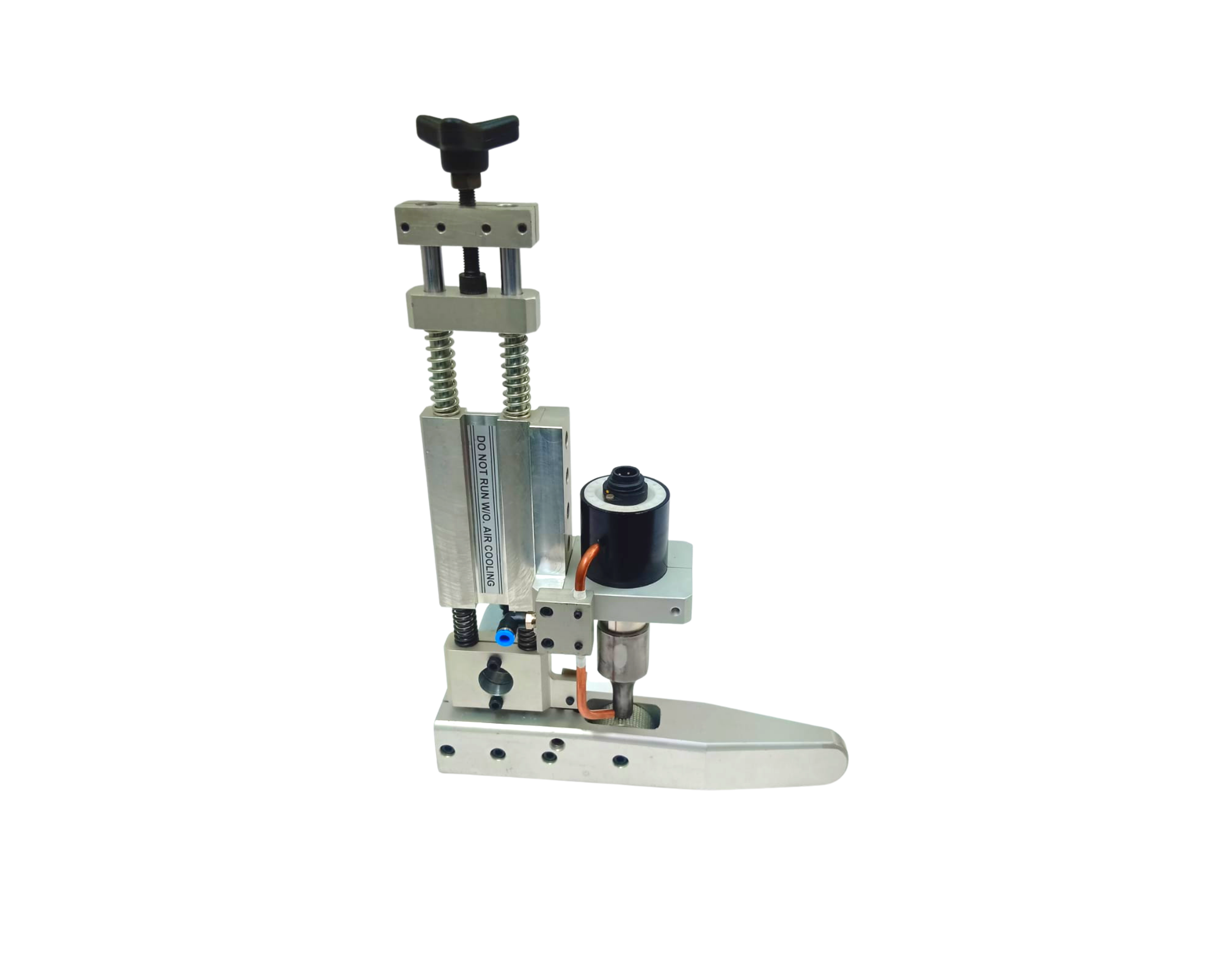

Ultrasonic Sealing Machine

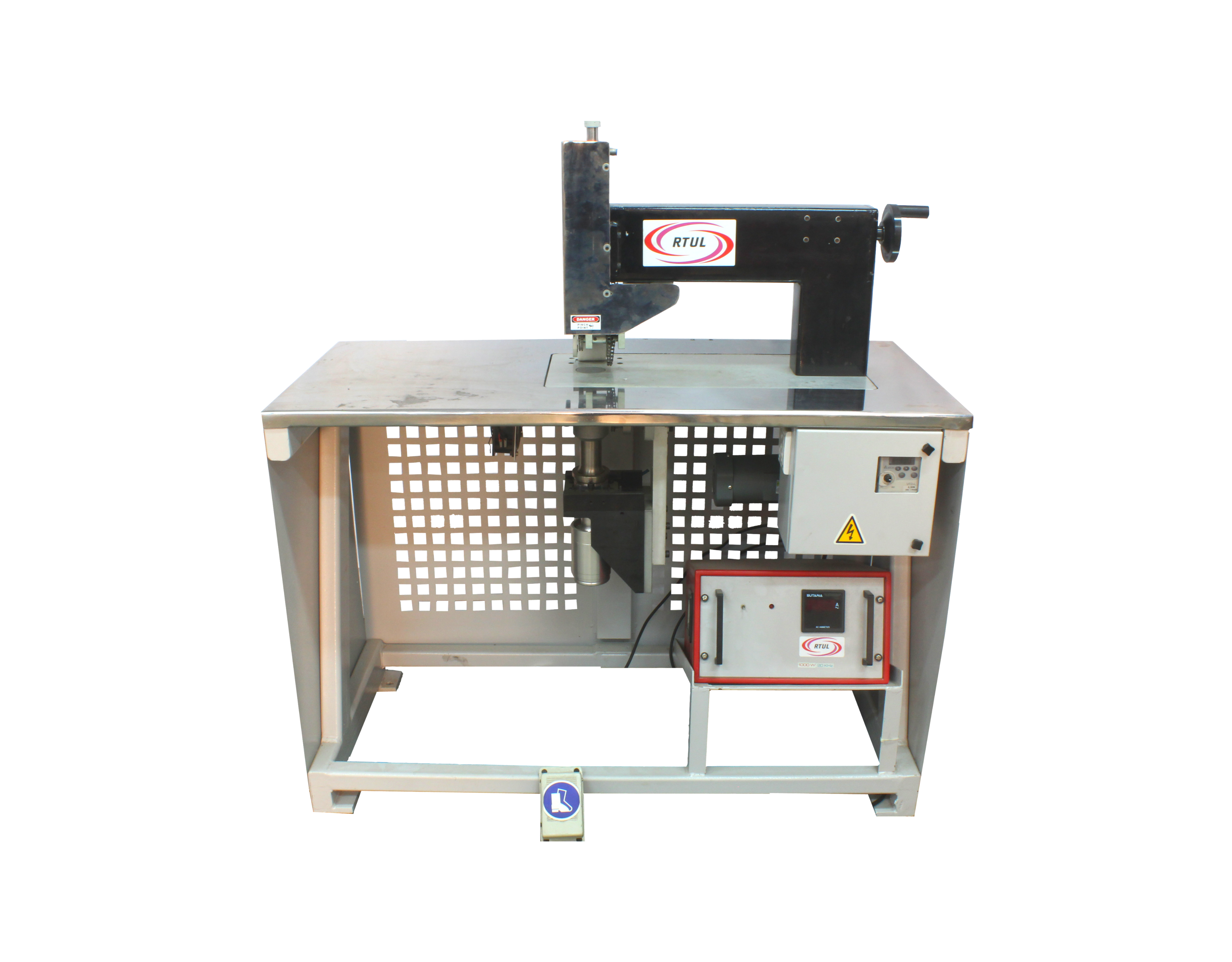

Ultrasonic continuous sealers provide a big benefit over conventional stitching methods. The system can perform two manufacturing processes in one flow i.e (Cut & Seal), there is no wearing due to steel sonotrode and prevents the material from fraying.

The Ultrasonic Sealing System is designed with a motor, roller, electronic control & working table for sealing of Fabrics, Plastic Films, Laminated paper, Non-Woven Fabrics, Filters, etc. It is a versatile Machine and the location of the horn and anvils enable flexibility and tight turns in sealing, This also provides an unobstructed view of the fabric in the processing area.

| Ultrasonic Generator |

SG-40-36-1000W/ SG -22-1000W |

| Ultrasonic Converter |

36KHz/SE 40/33 , 20KHz/SE 50/44 |

| Horn | Titanium |

| Working GSM |

50-140/ Upto 300 |

|

M S Roller anvil for Stitching |

Yes, 60 mm Dia |

| Booster with ring | Yes (Titanium) |

|

Foot Switch |

10 Amp/ 250 V |

|

Bottom Legs |

M12 x 80 mm length |

|

Weld area (Width in mm) |

30 mm x 10 mm (max) |

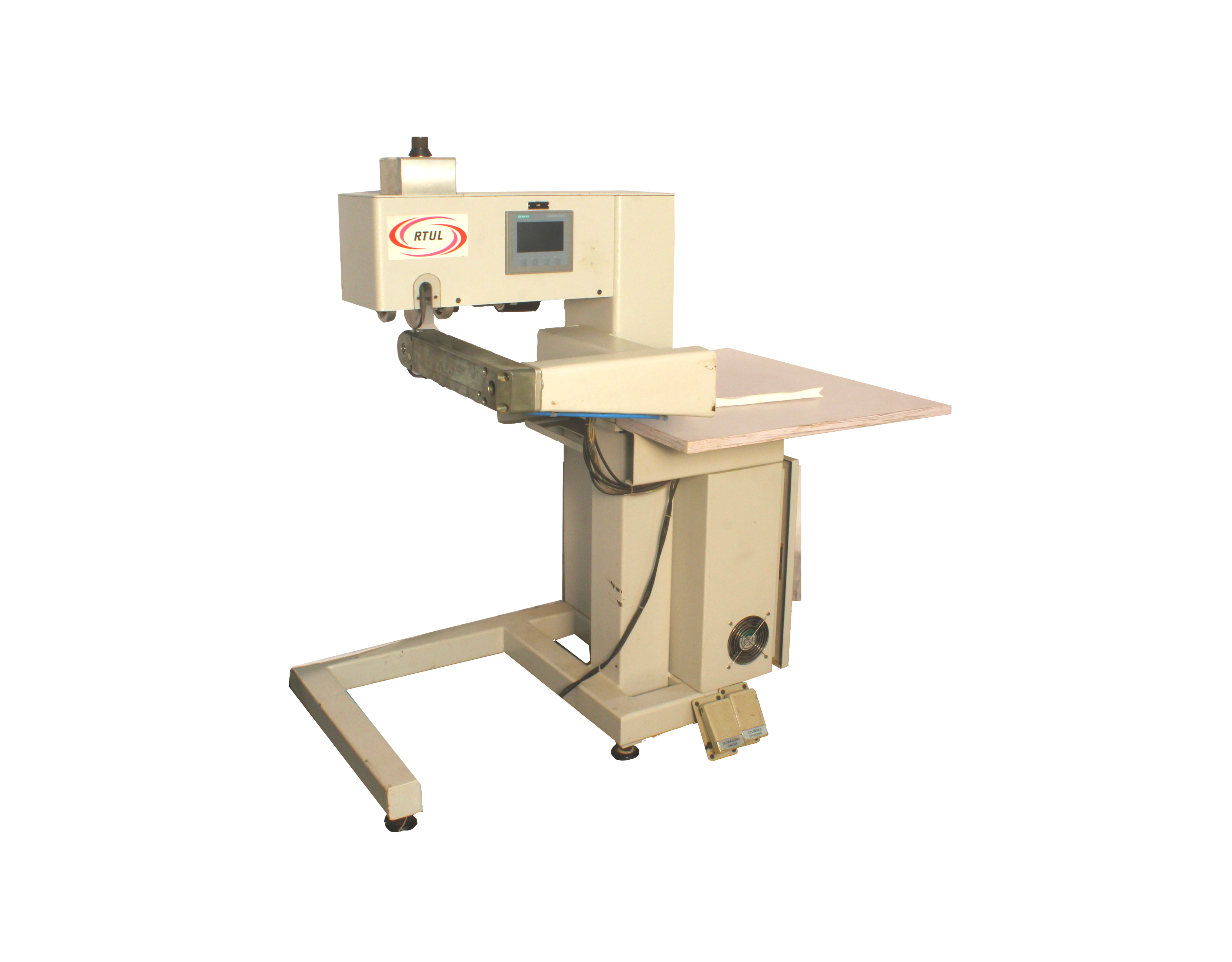

| Ultrasonic Generator |

UHG-35-1000W |

| Ultrasonic Converter |

35 KHz/SE 3512 |

| Horn | Titanium |

| Working GSM |

Upto 200 |

|

Rotary motor for Sealing head |

Yes |

|

PLC + HMI (for system controls) |

Siemens made |

|

Foot Paddle |

2 Nos |

|

Bottom Legs |

M12 x 80 mm length |

|

Weld area (Dia in mm) |

6 mm (max) |

|

Proportional valve |

Festo made |

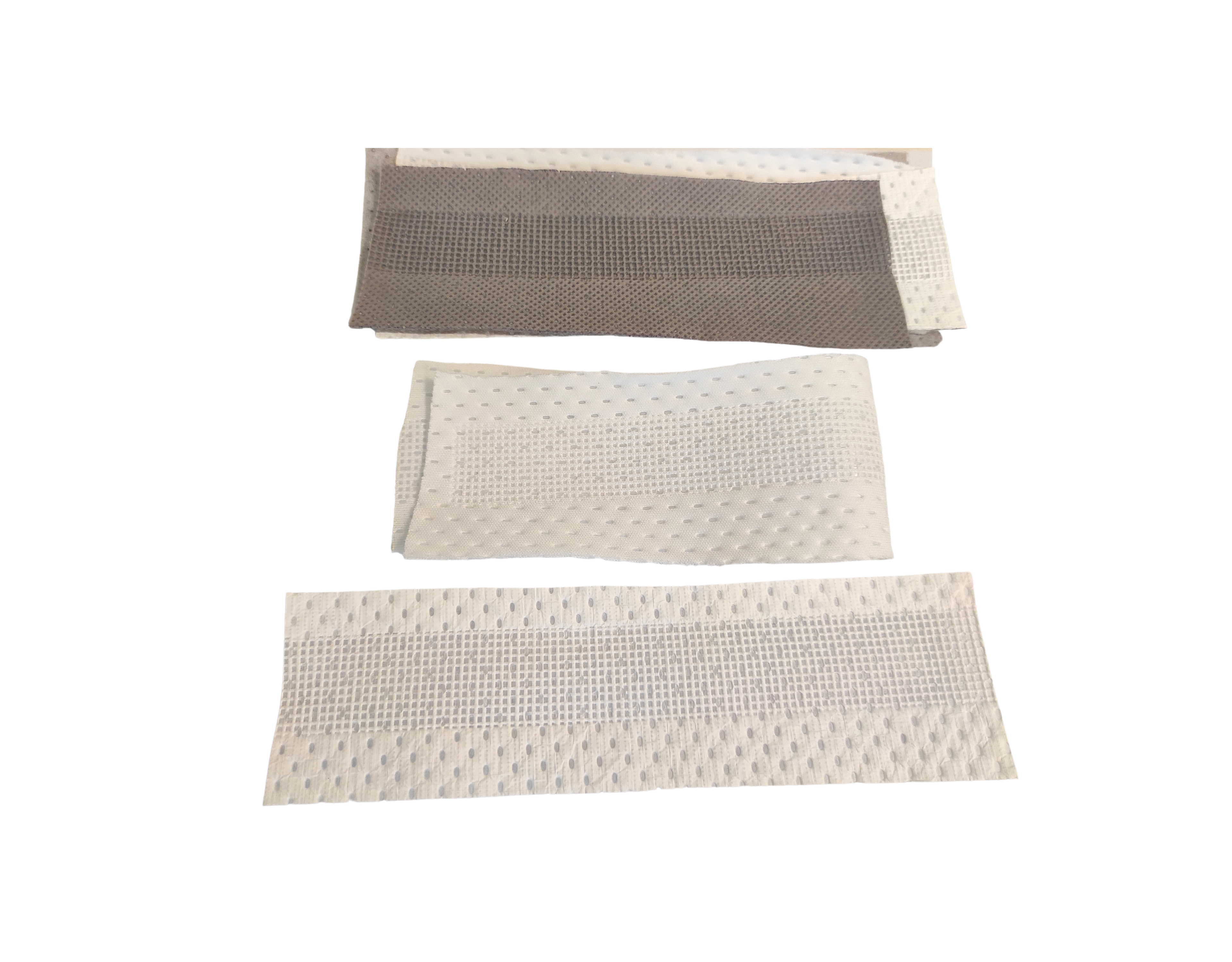

- Protective garments

- Disposable hospital gowns

- Shoe Covers

- Face Masks

- Infants’ nursery garments

- Filters

- Bags

- Curtains

- Sails and web splicing

- Sealed edges and seams with no stitch holes prevent penetration of chemicals

- liquids

- Bloodborne pathogens , or particulates

- Filter bags

- Health care articles

- Medical mattresses and pillows

- Needle felts

- Operations sheets

- Foils

- Bullet proof vests

- Blinds and awnings

- Pleated filter

- Shower curtains

- Spacer fabrics

- Seat covers

- MBR-modules

- Outdoor garment

- Medical garment & drapes

- Sport garments

- Vehicle interior and insulation item

- Protective cat covers

- Sunshades and many more

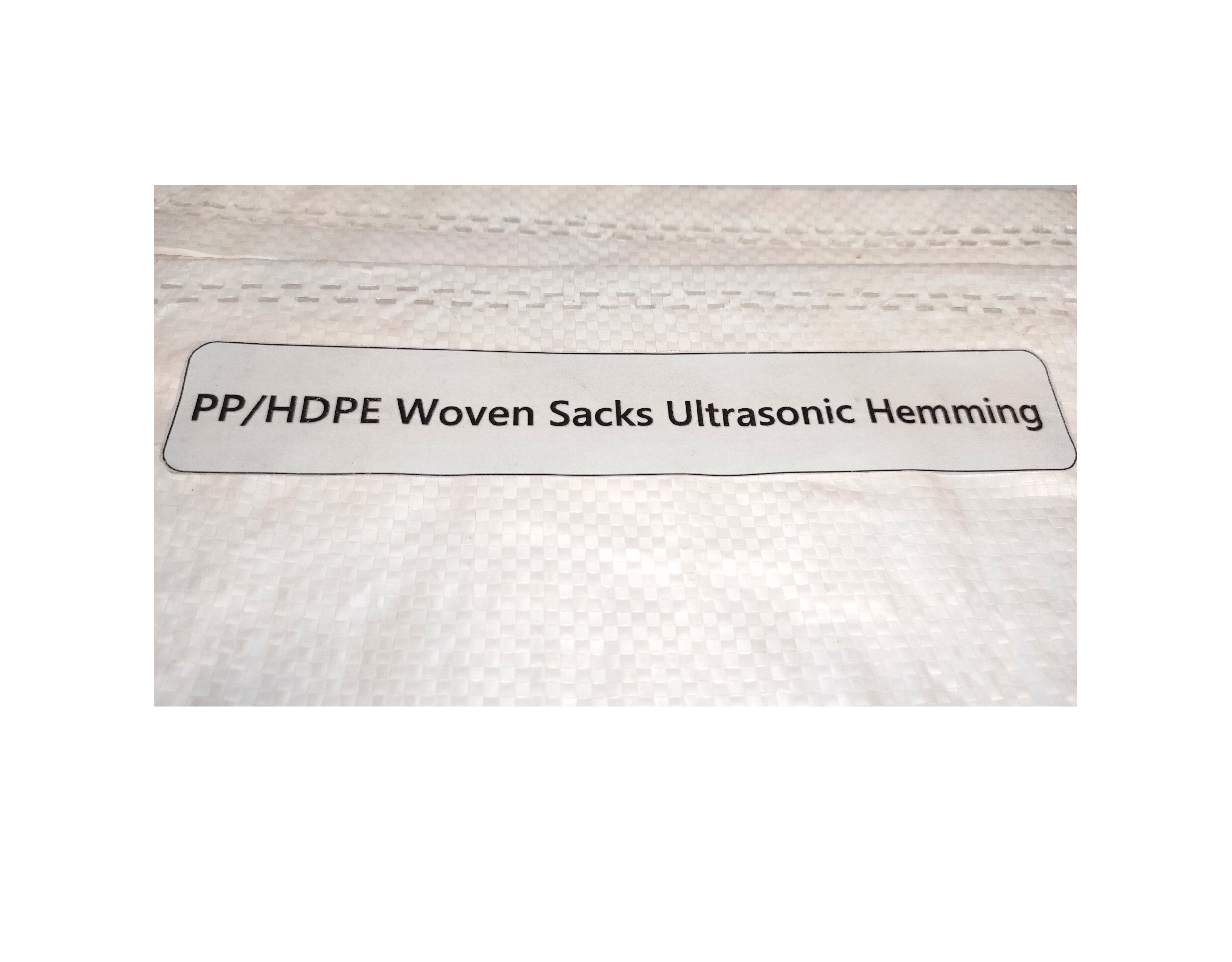

.png)

.png)

.png)