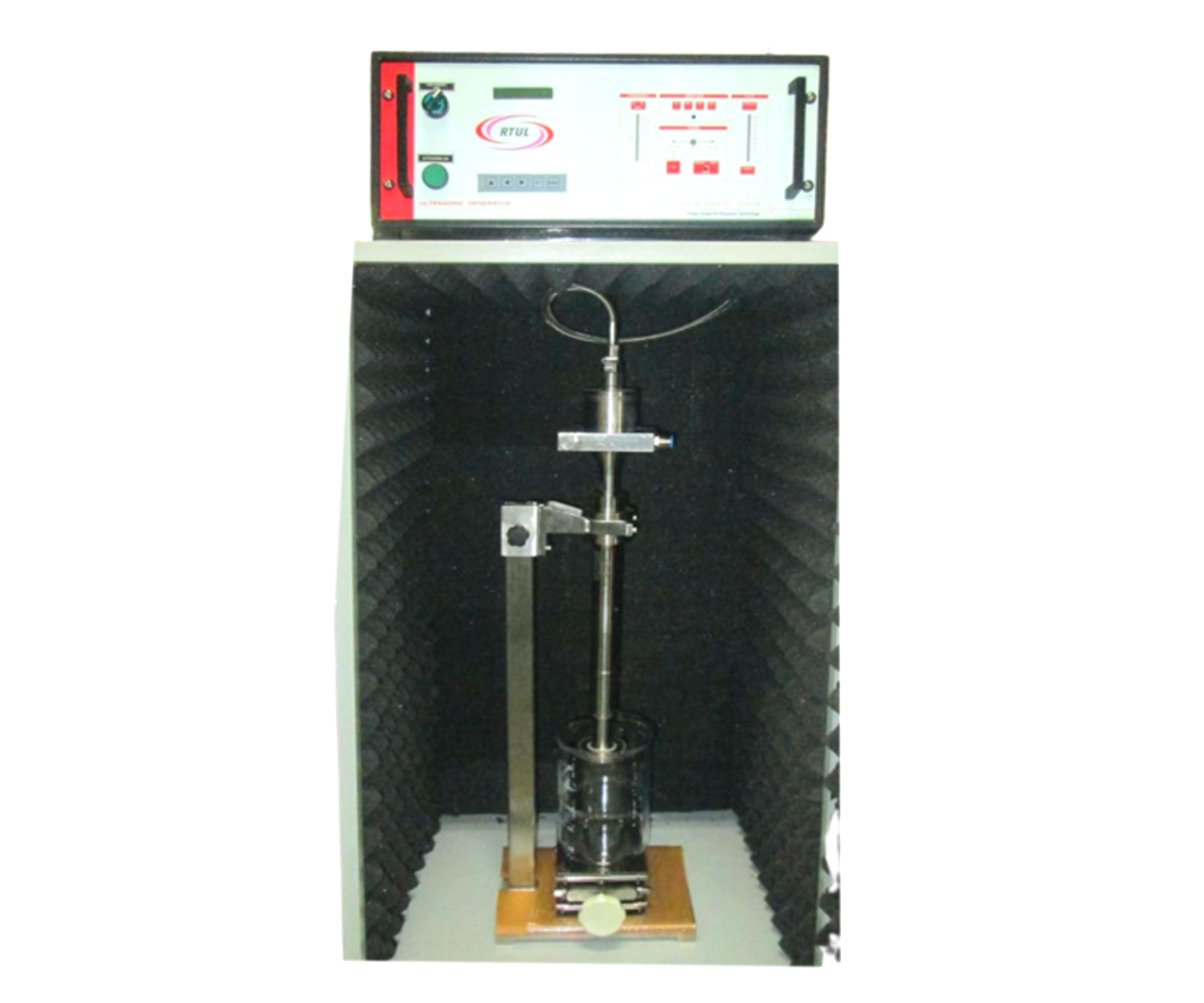

Ultrasonic Lab Processors - Sonic Lab

RTUL’s new Sonic Lab range of Ultrasonic Lab processors is being designed to meet the challenges of the Sonication process and feasibility trials of its suitability in various chemical processes like emulsification, particle size reduction, crystallization, agglomeration, dispersion, etc.

Sonic Lab will be the first such equipment with a comprehensive integrated process measuring controlling unit. It will be an effective tool for establishing the sonication process not only in the laboratory but also on the plant level.

RTUL’s Ultrasonic Lab Processors / Sonic Lab Processors are very adaptable in usage. It flawlessly processes organic and non-organic materials/ substances.

Read More

- Power supply – 85V AC to 265V AC, 50/60 Hz, 1Ø

- Ultrasonic power output – 500 W Average (Model SL-500), 150 W Average (Model SL-150), 60W Average (Model SL-60), (Other Outputs Optional)

- Frequency – 20/35/50/70 Khz single, dual or triple output

- Timer – Microprocessor controlled upto 999 min. (with lapse me display)

- Processing Volume – Upto 500 ml (Standard probe dia. 12.5mm) – SL-500, 0.25 ml to 10 ml (Standard probe dia. 3mm) -SL-150, 0.25 ml to 5 ml (Standard probe dia 3mm)- SL-60

- Data Storage/ Transmission – RS 485/Bluetooth/USB

- Multi Frequency.

- Online Temperature Monitoring.

- Full Amplitude Control:.

- Constant power mode.

- Proprietary Sonogamy tool.

- Auto Tuning.

- Program in Sequence.

- Continous/Pulse Mode.

- Touch Screen Control.

- Ease of Operation.

- Dispersion

- Suspension

- Emulsification

- Homogenization

- Degassing of liquids

- Acceleration of chemical processes

- Sonochemistry

- Crystallization

- Extraction

- Cell disruption

- Automization

- Agglomeration etc.

- Preparation and processing of samples are greatly accelerated.

- Tremendous improvements in throughput and hence faster processing of large number of samples.

- Improvements in analysis results due to more homogeneous samples.

- Cost savings owing to elimination of certain production steps and consumables.

- Temperature sensitive substances are not damaged.

.png)

.png)

.png)