An ultrasonic processor is a powerful device with myriad applications in industries like F&B, Pharma, biotechnology and chemicals. They are ideal for dispersing, homogenization, deagglomeration and emulsification. The devices are reliable and target the ultimate cleansing procedures.

Being most useful in lab-scale applications, the right manufacturer like RTUL Group can provide the perfect device. All liquid processing tasks can be accomplished with their powerful components. Ultrasonic cleaners have been around for several years. However, the new generation ones have evolved from customer needs.

As a well-known ultrasonic machine manufacturer in India, RTUL Group offers a perspective on this product profile. We break down the theoretical details for prospective users.

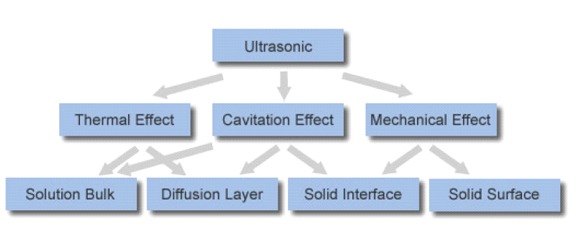

Working mechanism of an ultrasonic processor in solid-liquid cavitation build up

What does a typical device comprise of?

It has 4 key components:

⦁ Ultrasonic generator- serves as the power source

⦁ Piezoelectric transducer-converts electrical signals to mechanical vibrations

⦁ Barbell horn- mechanical vibrations are transmitted here into the liquid

⦁ A reactor chamber -It holds the liquid for processing

In the reactor, cavitation occurs. Bubbles are formed and implode within the chamber. All particles breakdown during the process uniformly.

RTUL Group makes high powered energy creators. An automatic tracking system for frequency helps to monitor the process of cavitation. If you wish to avoid corrosion then invest in the tool head that is made from a material like titanium. There are other materials like stainless steel and carbon steel which can be used to make the equipment.

We make customized processors which can be applied as:

⦁ Homogenizers

⦁ Anti-scaling ultrasonic processors

⦁ Cell disruptors

To get the intensive cavitation effect, experts have to take into account the thermal and mechanical effects. The thermal effect is caused in the solution due to the medium of propagation introduced. Friction is created from the medium boundary. When the bubbles collapse and break down heat is generated.

How much would it cost to invest?

When you contact a manufacturer to know the Ultrasonic Machine price, be ready to discuss all your needs. The cost of ultrasonic processors and cleaners vary significantly based on their intended use, size, and features.

It is essential for potential buyers to engage directly with manufacturers to discuss their specific requirements and obtain a customized solution. Each ultrasonic processor is designed to fulfil particular functions, whether in industrial-scale production or small-scale laboratory research. Manufacturers can provide detailed quotations and suggest the most suitable models based on the intended application and processing needs.

Manufacturer Collaboration

Contacting a reputable manufacturer is a vital step in acquiring the right ultrasonic machine price. Professional manufacturers, specializing in ultrasonic technology, offer consultation services.

The team, comprises of technical experts and field specialists to guide buyers through the selection process. You are assured of the chosen ultrasonic processor meets their operational demands and regulatory standards. We provide training and support to buyers for using the equipment. It can be utilized efficiently and safely, for maximum benefits.

Understanding the components, applications, and working mechanisms is essential for optimizing their use. Engaging with the right ultrasonic machine manufacturer in India can help businesses and researchers procure the right equipment.

.png)

.png)

.png)