The Task

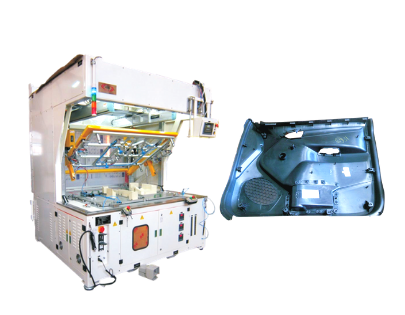

To design an ultrasonic plastic welding system to weld the door panels. As plastics have continued to replace other materials in the design and manufacture of automobiles, the joining of plastic components has increasingly become a critical issue thus it becomes necessary to develop rapid welding techniques for welding such assemblies.

The Solution

In this case, the challenge was processed by designing an ultrasonic plastic welding system with a new robot which welds in fraction of seconds i.e almost 30 secs faster than the traditional machine. The system consists of four actuators with a parking slot designed in it. In order to work on the space constrain, it was designed in such a manner such that the only two working actuators are out of the parking slot for the process & the spare ones are parked inside it.

The Advantages

- Low cycle time as compared to traditional machines

- Automated process and low heat generation

- Perfect welded rivet shape

- No damage cause to the surface finish

.png)

.png)

.png)